Suppose you go to the bath and need to receive a phone call. It is urgent and essential.

How will you do that? Your hands are wet now. Don’t worry; the hydrophobic screen glass of smartphones can make this happen. Even if your hands are dipped in the oil, oleophobic glass coatings can never disappoint you.

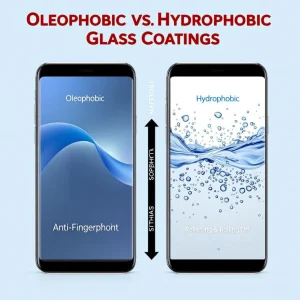

Do you want to know about oleophobic and hydrophobic glass coatings? Today we will shed light on the Oleophobic vs Hydrophobic Glass Coatings and discuss which is better for you.

What is oleophobic glass coating?

Disintegrate the words into the alphabet and understand the meaning.

Oleo means oil—phobic means to hate or repel.

Can you guess what is the definition of oleophobic glass coatings? These glass types come with oil repellents coated on their surfaces. Deploying the oleophobic glass materials can help elevate the consumers’ experience. Plus, it ensures you get a seamless touchscreen experience even if your hands are wet in the oil.

Do you know how oleophobic glass coatings work?

They don’t absorb the oil particles. Make them dispersed on the screen. Wiping them becomes an excellent and efficient task for the users.

What is hydrophobic glass coating?

Consider the disintegration of the hydrophobic word, too.

Hydro means water. While the phobic refers to the repel.

Now it is easy to define such a glass type. A hydrophobic glass offers excellent water-repelling features. It doesn’t absorb the water particles. Keeps the screen clear of the water. And increases the experience by expanding the touch sensitivity. Whether you use a smartphone or a tablet, hydrophobic glass coatings make a perfect place in these components.

Oleophobic vs Hydrophobic Glass Coatings: Key Differences Between Both

Oleophobic and hydrophobic glass coatings have different purposes and types of work, but their goal is one. It is to impress the consumers and increase their overall experience when interacting with the screen.

Primary Purpose

The primary purpose is often based on the working features. For instance, if something is stain-resistant, its primary goal is to avoid the stains and enjoy the next-level experience.

Let’s dive into the primary purpose of each material.

Oleophobic glass coatings protect the phone screens from the oils. If you spread a drop of oil on the surface, it remains the same without any effects. Later, you can wipe it out like there was no drop. No absorption phenomenon can cause disturbance in the screen experience.

Hydrophobic Glass Coatings offer the same experience but with the water. Whether you soak the phone in water or put your wet fingers on it, the water drops remain in drop form. The wiping and cleaning are a no-brainer.

Surface Interaction

If you drop water or oil on your phone screen and they don’t get absorbed, your first question— how did that just happen?

The logic is simple. There is a unique surface interaction that makes it impossible to absorb. Let’s discuss this in both materials.

Oleophobic glass coatings work on the friction mechanisms. They create a low-friction layer. This layer prevents the adherence of the oil particles and avoids sticking.

Hydrophobic glass coatings believe in the beading phenomenon. They reduce the surface tension of the water. It leads to water sitting as the drops on the surface due to decreased surface tension.

Material Composition

Suppose you have two types of glass and need to confirm which one is hydrophobic and which is oleophobic. How will you do that before dropping the water or oil on it? Learn about the material composition.

The material composition of the oleophobic glass is fluoropolymers. They are a good repellant for oil particles and provide an excellent consumer experience.

On the other hand, the water repellent comprises silicon or other nano-coating. Such a coating can elevate the user experience by reducing surface tension and providing safety from water.

Kestävyys

Which glass is more durable in your opinion? Grab similar quality glasses of both types. Keep them side by side and apply the same force.

Make a rough guess about which will break first.

The oleophobic glass comes with a better resistance to wear and damage. Therefore, it is helpful for high-class applications such as phone screens.

Hydrophobic Glass Coatings are good but wear rapidly after constant use. Plus, they don’t offer the same durability as the oleophobic glass materials.

Sovellukset

For what purpose do you want to deploy the glass materials? Every application comes with a different use. Some glass materials are constantly being used in water. Consider the example of window glasses. The rainwater constantly hits them. On the other hand, phone screens often face oil-soaked fingers.

Let’s divide the applications of each material.

Oleophobic glass coatings are known for their extensive applications in premium applications.

Consider the examples of:

- Älypuhelimet

- Tabletit

- Älykellot

These materials don’t need the smudges to affect their surfaces. Oleophobic glass is the ideal choice for keeping them clean.

Hydrophobic Glass Coatings are specialized for protection from the water. They invite the glass materials under constant water applications. Common examples of the hydrophobic applications include:

- Automotive windshields

- Aurinkopaneelit

- Camera lenses for outdoor protection

| Ominaisuus | Oleophobic Coating | Hydrophobic Coating |

| Primary Purpose | Repels oils, especially fingerprints, to keep high-touch surfaces smudge-free | Repels water to keep surfaces free from water droplets and moisture |

| Surface Interaction | Prevents oils from sticking, creating a slick, low-friction layer | Reduces surface tension, causing water to bead up and roll off |

| Durability Against Wear | More durable for high-contact surfaces, designed to withstand frequent touch | Less durable with touch, best suited for low-contact, moisture-prone environments |

| Material Composition | Contains fluoropolymers or similar oil-repellent compounds | Uses silicon or nano-coating materials specifically designed to repel water |

| Application Areas | Electronics like smartphones, tablets, and smartwatches | Automotive glass (windshields), solar panels, camera lenses, and building windows |

Johtopäätös

Each glass coating has a different functionality. Based on your needs, you can opt for anyone you need. Generally, it is easier to decide between the two once your goals are 100% clear.

During your purchase, ensure you have the proper manufacturer who delivers the quality. Do you have that one?

Shenxunin lasinvalmistajat can be your one-stop solution. Dig out an enormous range of glass options. Select the oleophobic to hydrophobic glass materials. Bring in the quality. Explore the quality now!