We will offer you the best custom glass services

Shenxun Custom Glass manufacturer

Shenxun Glass was founded in 2003 and is a leading custom glass manufacturer. Our main products include 3D curved glass, tempered glass, Gorilla Glass, and dozens of other glass types. We provide a variety of custom glass solutions to customers around the world. Shenxun Glass has advanced glass processing technologies, including:

- Glass CNC processing

- Glass laser cutting

- Water jet cutting

- Color silk-screen printing

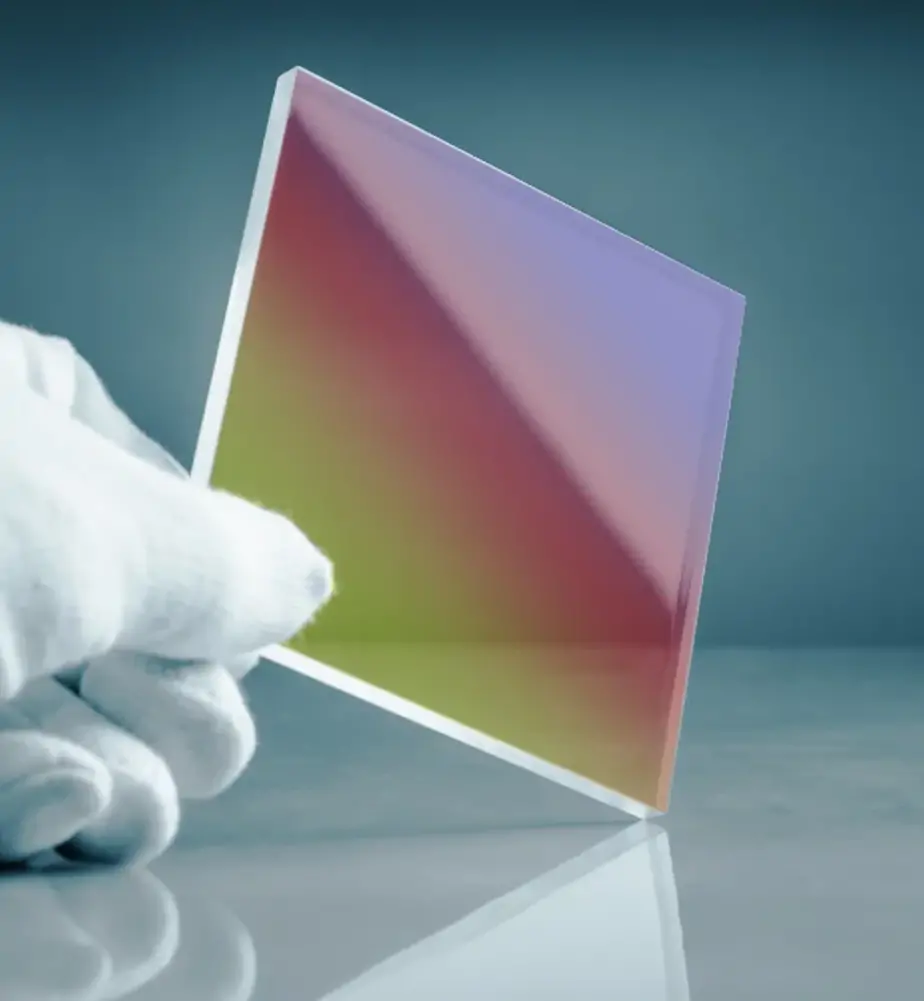

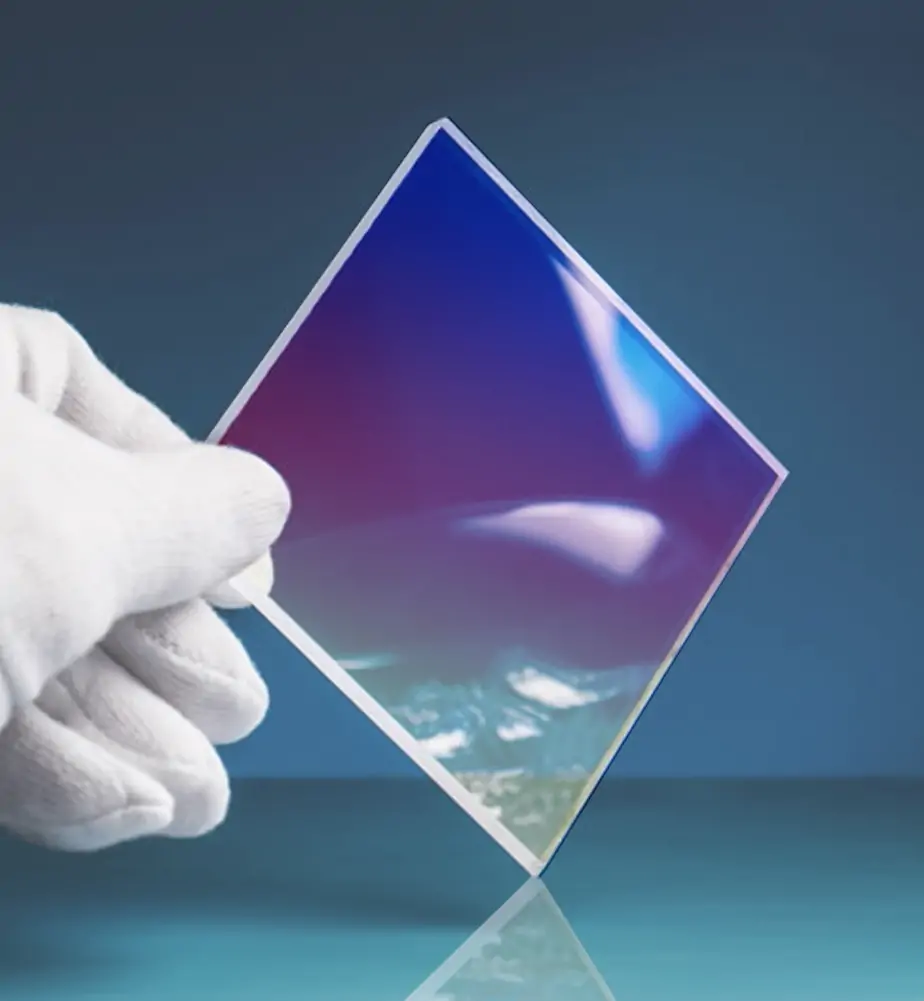

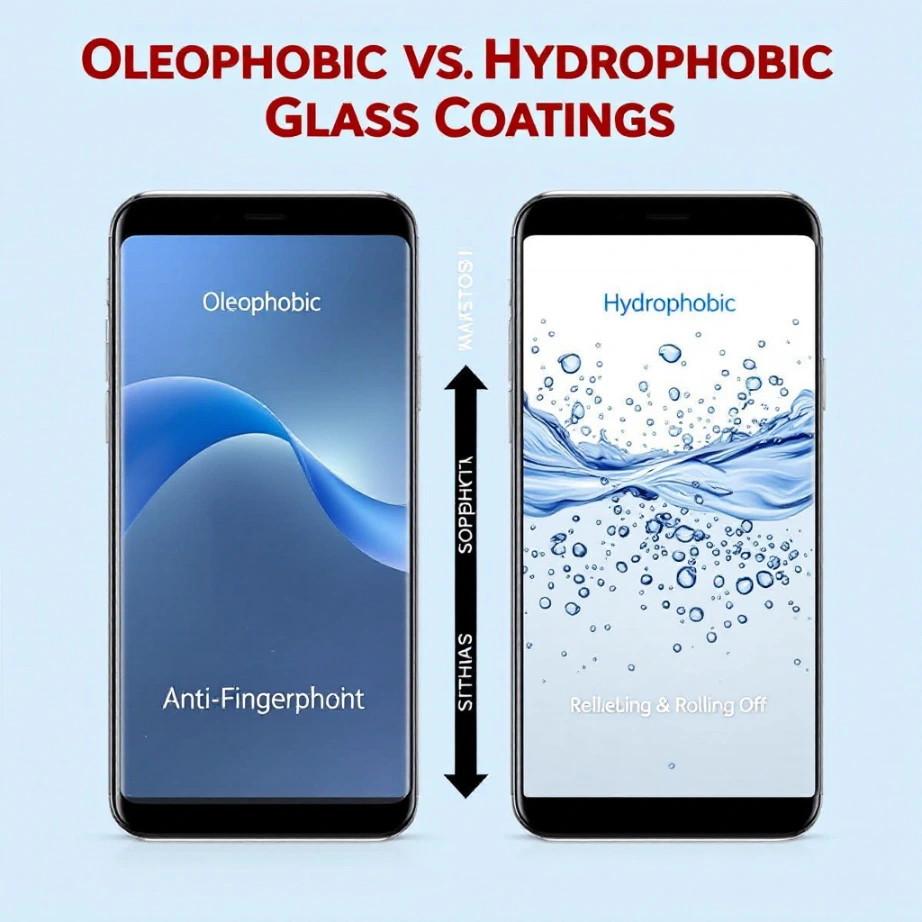

- Anti-reflective coating

- Anti-glare etching

- Mirror coating

- ITO coating, etc.

These processes ensure that our glass products meet the highest quality and durability standards. We strive to be your first choice for finding high-quality glass products. Contact us now to learn how to meet your glass customization needs.

Get a quoteYour Reliable Glass Fabrication Solutions Expert

Shenxun Glass provides high-quality glass manufacturing solutions. With years of industry expertise, we focus on customized glass products.

We have served customers in various industries, such as automotive, aerospace, smart home, etc.

Whether you need complex design or large-scale production, we have a perfect solution for you.

In this video, we take you through the complete process of making custom glass products. You will see our process, starting from the initial design.

Follow us. See how each step builds an excellent custom glass product.

Get a quoteOur Custom Glass Manufacturing Material

Your Glass, Our Process: Custom Glass Service

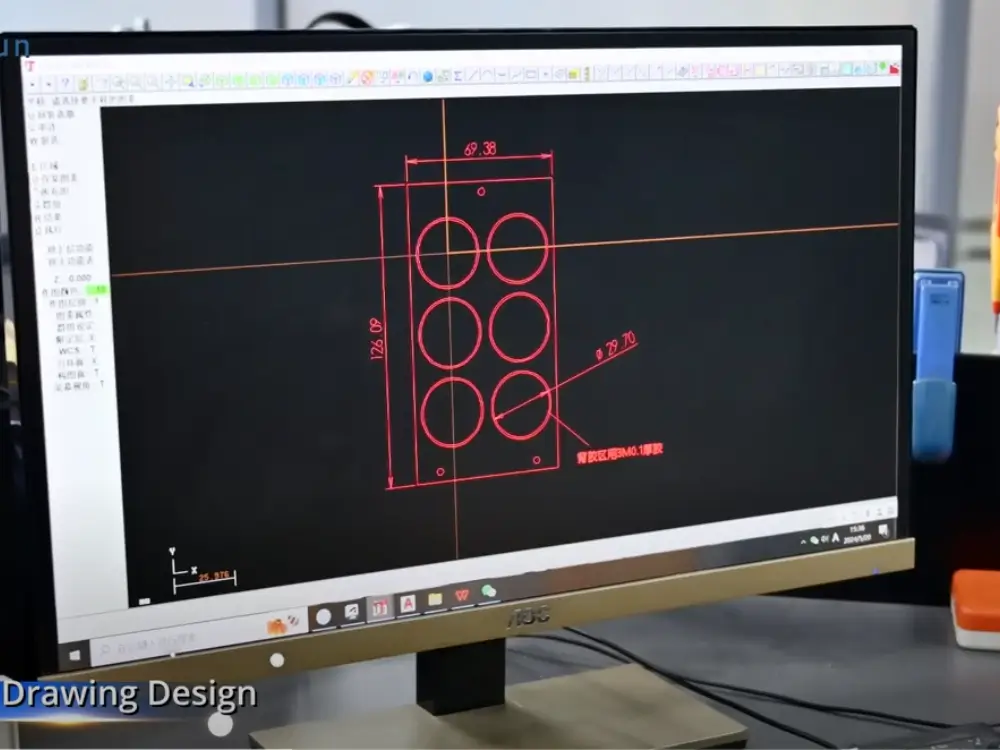

Professional designer customized solutions

Our designer collaborates with you to grasp your project’s exact needs. We use advanced design software to create detailed 2D and 3D models.

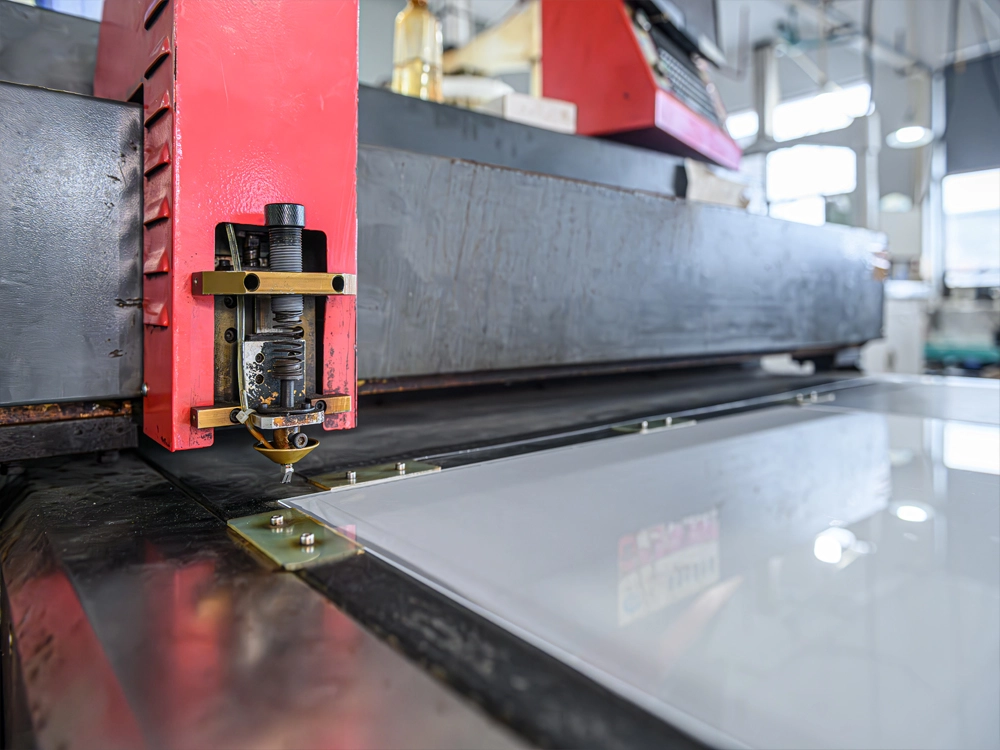

Precision cutting of glass materials

We use high-precision cutting equipment to cut Glass to exact sizes and shapes. This meets the design drawings’ requirements. We can ensure the accuracy of any cut, straight or curved. We also guarantee a smooth edge.

Glass CNC processing

We use advanced CNC processing technology to perform precision processing on Glass. CNC technology enables the creation of intricate forms, precise grooves, and detailed engravings.

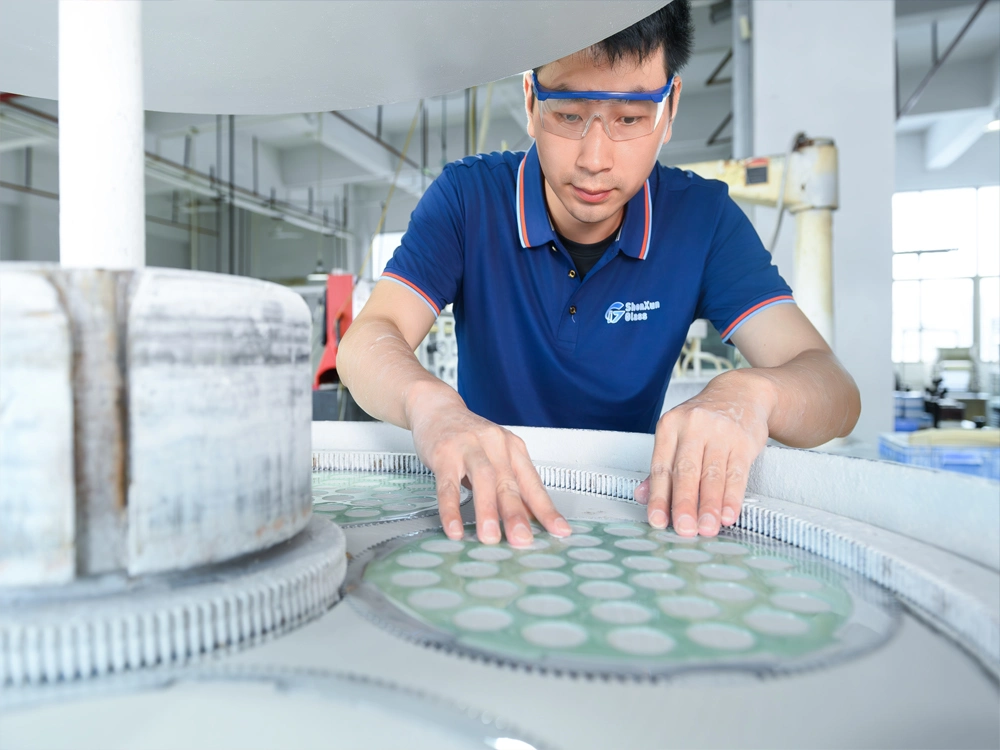

Grind the glass carefully

Glass grinding removes sharp edges from cutting. It makes the Glass safer and more beautiful. We employ precision grinders to hone glass edges into smooth, flat surfaces.

Glass edge processing

We offer various glass edge options, like chamfers and polished edges. Our precise processing ensures the Glass is safe and looks great.

Glass chemical strengthening treatment

Through chemical strengthening, we can significantly improve Glass’s strength and impact resistance. This process involves immersing the Glass in a special chemical solution. This creates a compressive stress layer on the Glass’s surface, enhancing its crack resistance and durability.

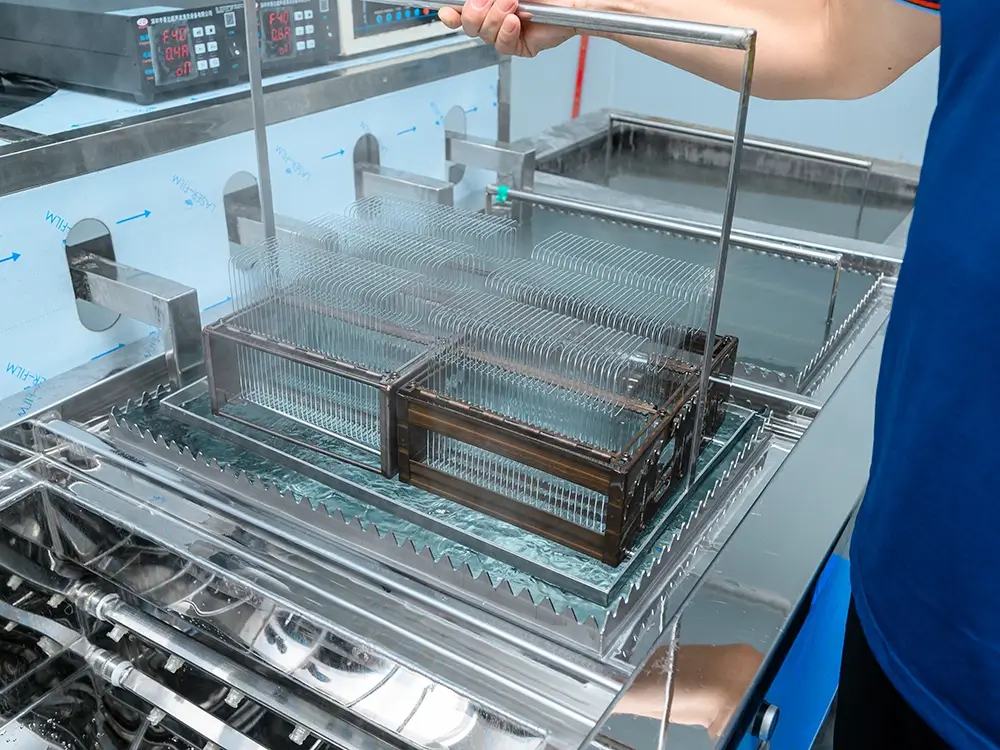

Ultrasonic cleaning of glass

After chemical strengthening, we perform ultrasonic cleaning on the Glass. This ensures the glass surface is entirely free of tiny particles and impurities. Ultrasonic cleaning can deeply clean the Glass and its tiny gaps. It ensures the Glass is clean for later use.

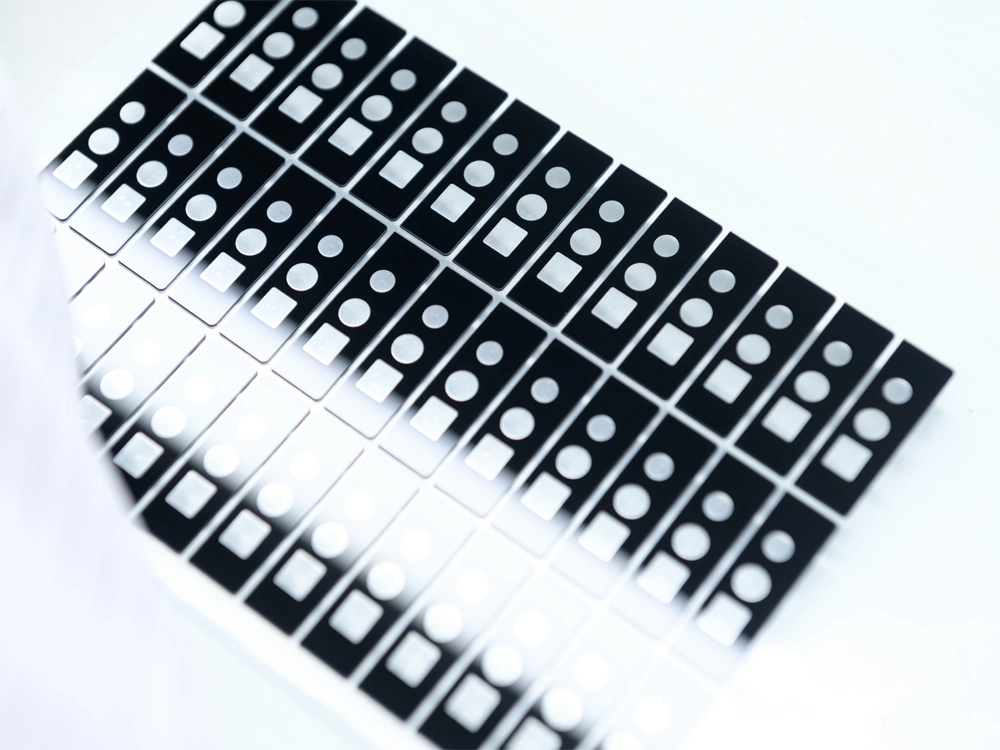

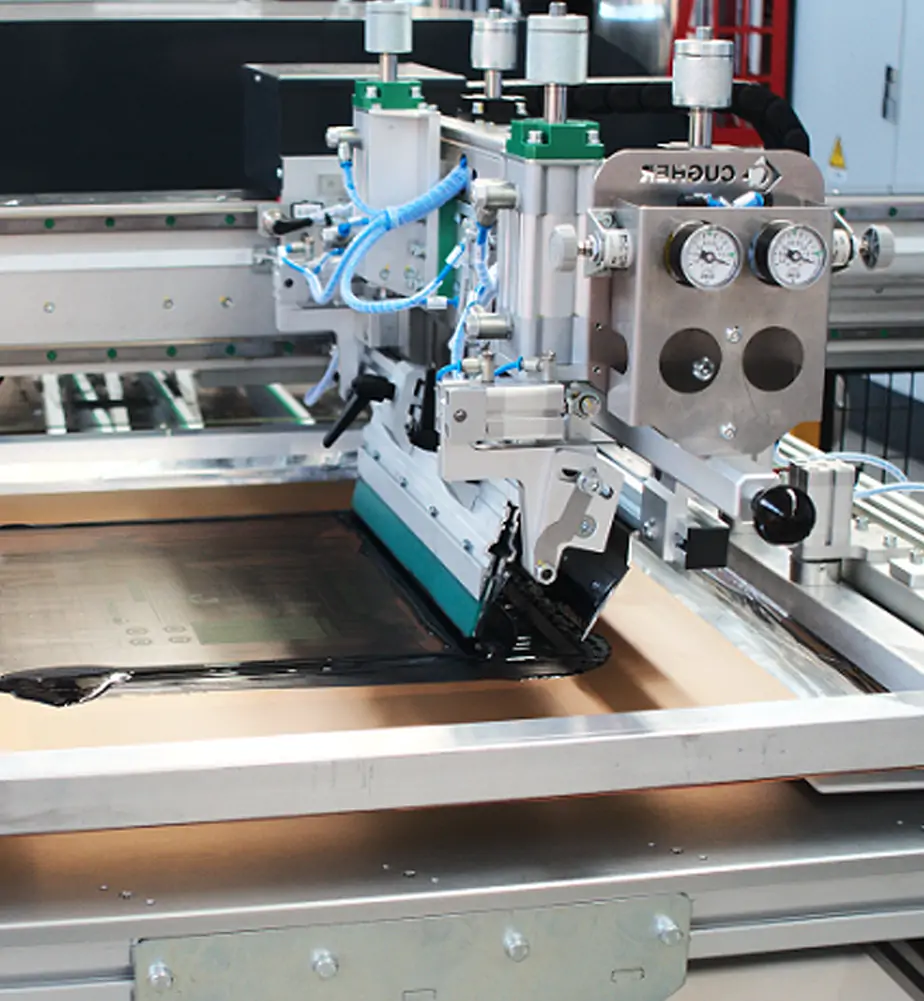

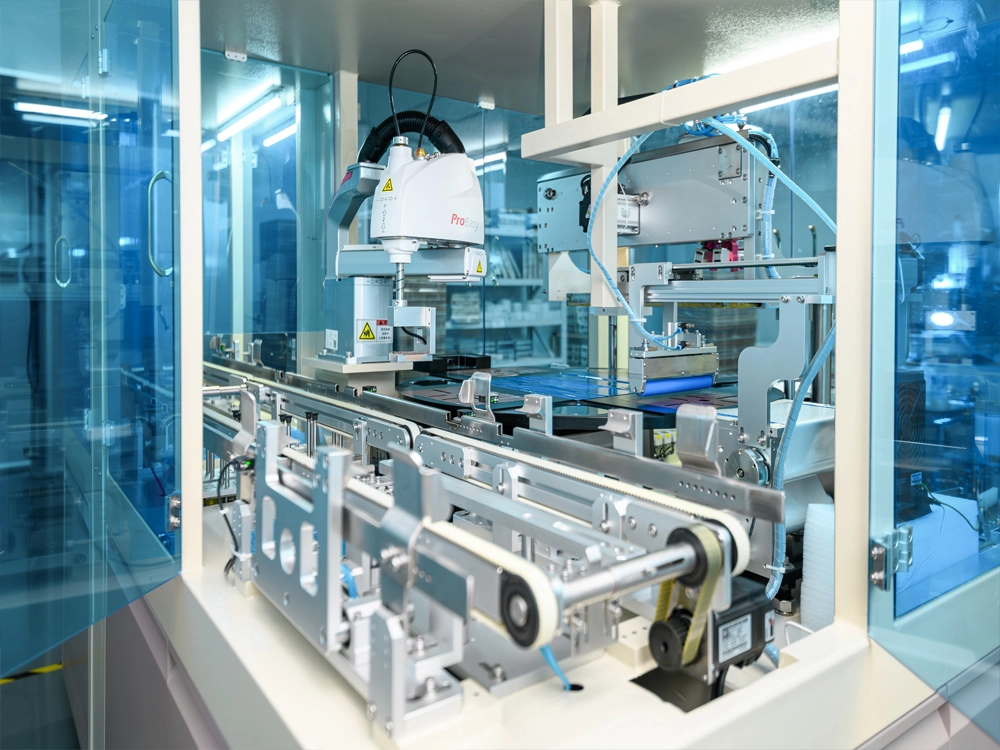

Dust-free silk screen glass workshop

We screen print the Glass in a dust-free screen printing workshop. This ensures the clarity of the pattern and the stability of the color. The dust-free environment ensures the quality and accuracy of the printing, meeting your high standards.

Drying glass

After screen printing, we dry the Glass to ensure the ink or coating is fully cured. The drying process can prevent the pattern from deforming by precisely controlling the temperature and time. This ensures the final quality of the Glass.

Adhesive backing for glass

To meet specific installation requirements, we provide adhesive backing for Glass. We can use high-strength adhesives to bond glass to other materials, like metal or plastic. This will add support or protection.

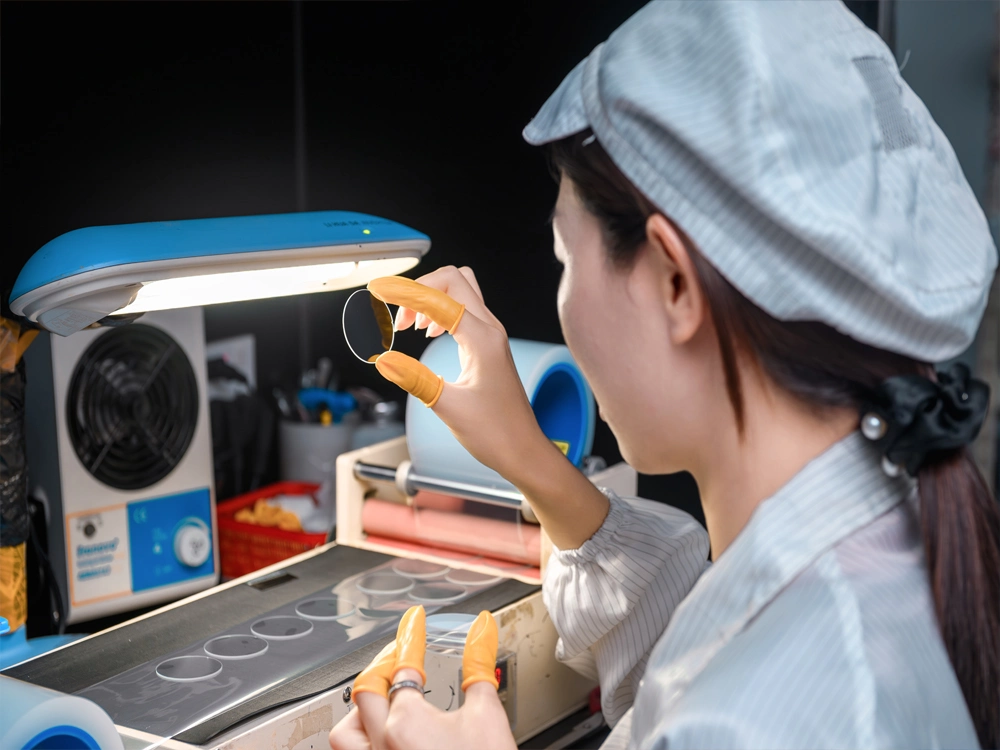

Strict quality inspection

We inspect each piece of Glass to ensure it meets your size, appearance, and strength requirements. Using advanced testing equipment and skilled staff, we find and fix any issues that may affect the final product’s quality.

Vacuum packaging

After all processing steps are completed, we vacuum pack the Glass. Vacuum packaging can prevent dust, moisture, and damage to the Glass during transport and storage. It will arrive in perfect condition.

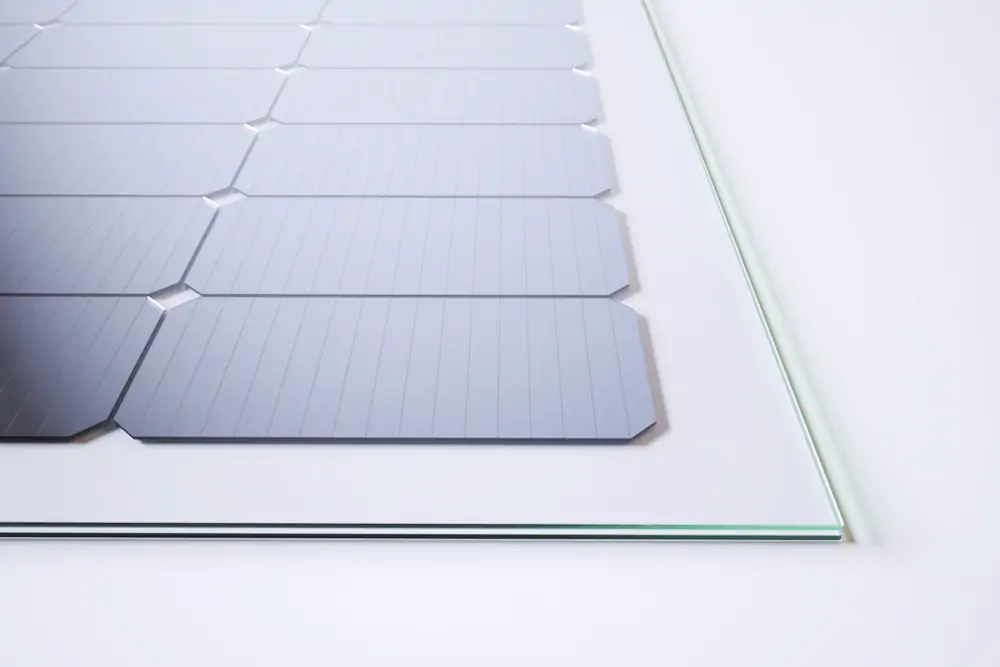

Custom Class products

From Design to Delivery: Your One-Stop Glass Solution

Tell us what you need

First, we will talk with you to understand your needs and requirements. We will discuss your application scenarios and design concepts in detail.

Next, we will analyze your needs. We will check the project’s feasibility and cost.

Provide you with one-to-one design service

We provide design services, including 2D/3D modeling, product drawings, PDF and sample designs.

We will adjust the design plan based on your feedback. This will ensure it meets your needs.

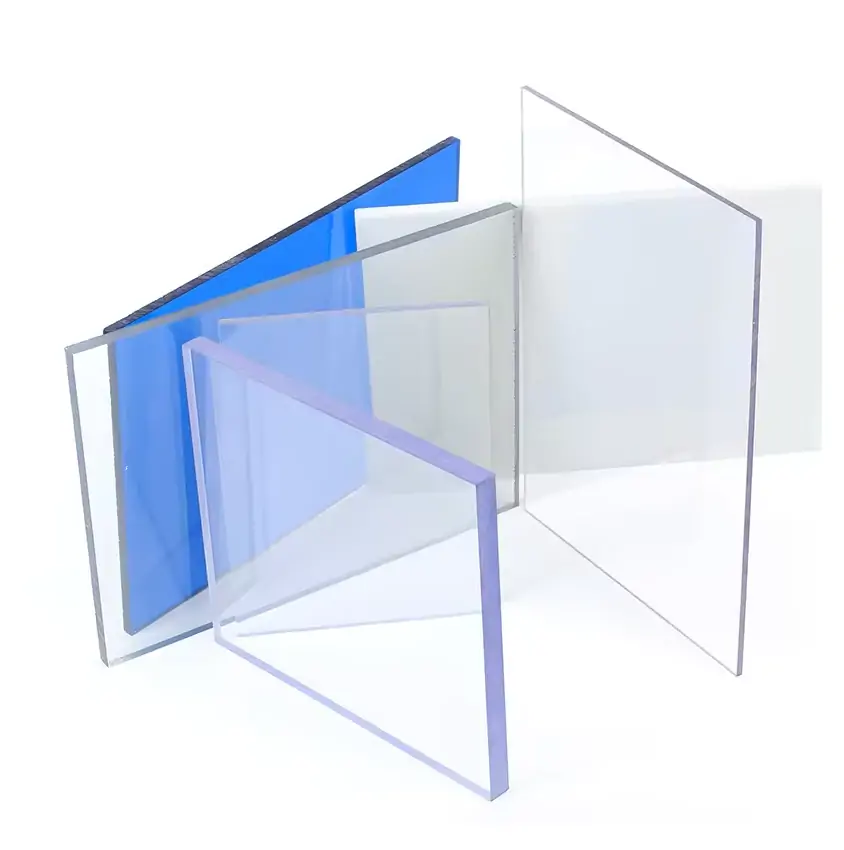

Choose the most suitable glass material

We recommend the best glass material for your project based on the project requirements. This includes different types of glass (such as Gorill glass, Schott glass, AGC glass, Panda glass, float glass, Quartz glass, etc.), color, thickness, and other materials with specific functions (such as anti-glare glass, coated glass, etc.).

Glass cutting and surface treatment

Our technical workers must cut and mold glass to the design drawings. This ensures accuracy and edge quality.

We provide various surface treatment technologies, including chemical strengthening, heat treatment, and coatings (anti-glare, UV protection, mirror).

Some special processes exist, including silk screen printing, engraving, punching, and edge grinding.

Production samples

We will make samples or prototypes first. You can then test them before we start production.

Our designer will make adjustments based on your feedback on the samples. This will ensure the product meets the final design requirements.

After the samples meet your requirements, mass production begins

We make detailed production plans, which ensure the project is completed on time and with quality. We will implement a strict quality control system in production, which ensures that every step meets your quality requirements.

Glass product processing and assembly

Shenxun Glass offers services to improve the product’s look and performance. These include fine polishing, assembly, and special coating.

We provide assembly services for glass and other components to deliver a complete solution.

Strict product testing

The glass drop ball test is a widely employed physical evaluation technique. It evaluates the impact resistance and strength of glass materials. A steel ball of standard weight is dropped from a specified height. It impacts the glass surface. The glass’s impact resistance can be judged by observing the cracking and damage.

Packaging and logistics

We design packaging for glass products, which can prevent damage during transportation.

We provide flexible logistics, including domestic and international shipping. We will deliver your products to your location on time.

1 year warranty service

We offer 1 year warranty services, including inspections, repairs, and replacements, to ensure your long-term satisfaction.

Shenxun also provides long-term tech support and customer service. They quickly resolve any problems you encounter while using their product.

Why choose Us

Choose us for our quality products. We can make custom glass products of your exact size and thickness for small or large projects.

Quality

We know that our products are the key to our success. So we use the best technology and quality control to ensure our custom glass products meet industry standards. Every step of the process is tested and reviewed. We guarantee our customers the best quality glass products.

Service

We offer excellent customer service from start to finish. We understand each project is unique, so we provide customized glass solutions to meet different needs and budgets. The service team at Shenxun Glass will answer your questions and help you.

Our Mission

Shenxun Glass aims to improve people’s lives by providing high-quality glass products and excellent service. We are committed to enhancing glass solutions to drive progress and sustainability in the industry. We want to be the best at making glass for buildings and homes.

Our Customers

Shenxun Glass serves many industries, including smart homes, display cover glass, and wearables. We work with international companies and local businesses. We value our clients and their trust. We listen to our customers and use their feedback to improve our products and services.

Custom Glass Fabricafion

What Our Customers Say

Design With US

Every project is different. So we will customize your product to your exact specifications. Our experts will work with you to ensure the solution meets your expectations.

At Shenxun Glass, we innovate and keep looking for new ways to make glass. Partner with us and add unique value to your projects with the latest innovations.