Customized Services

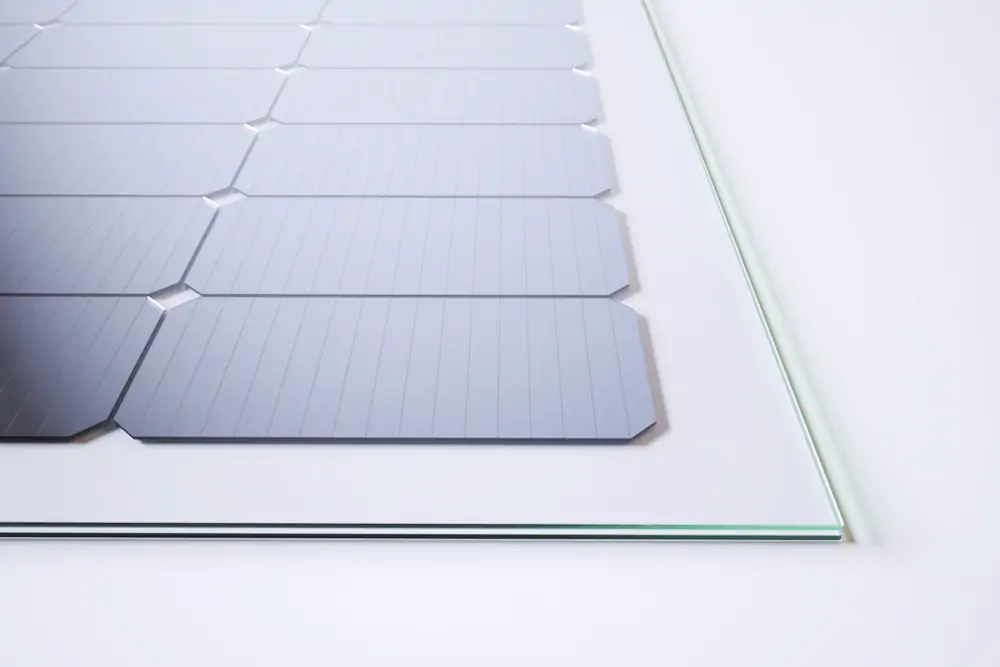

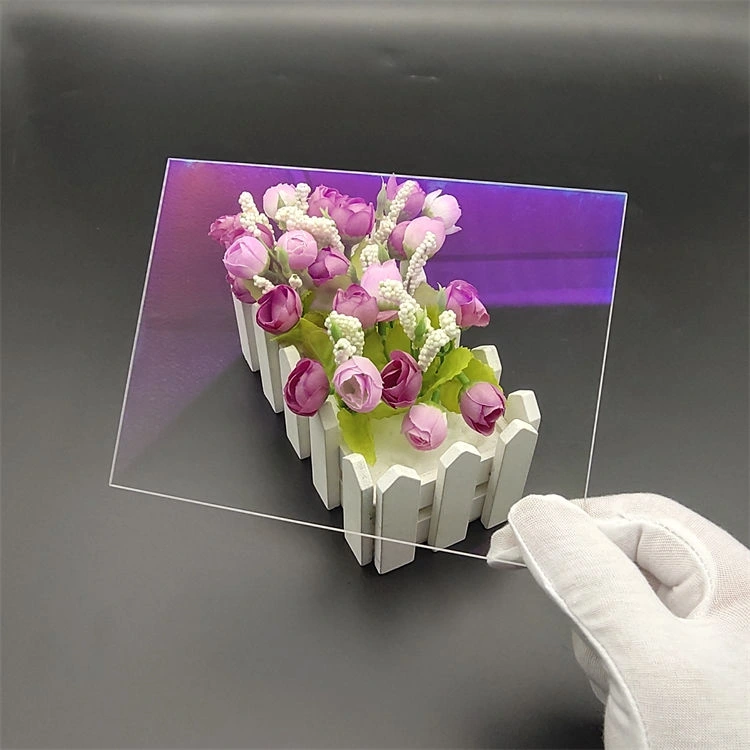

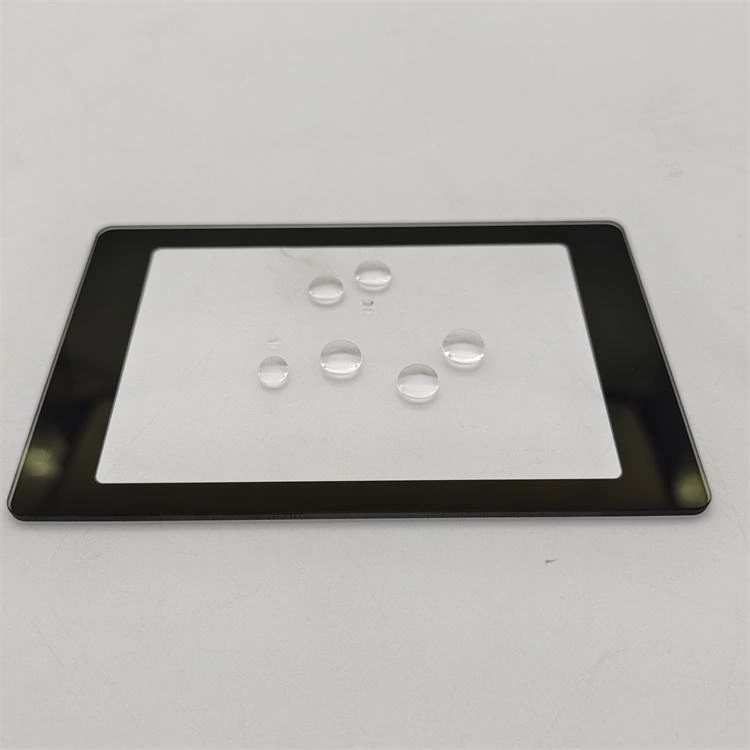

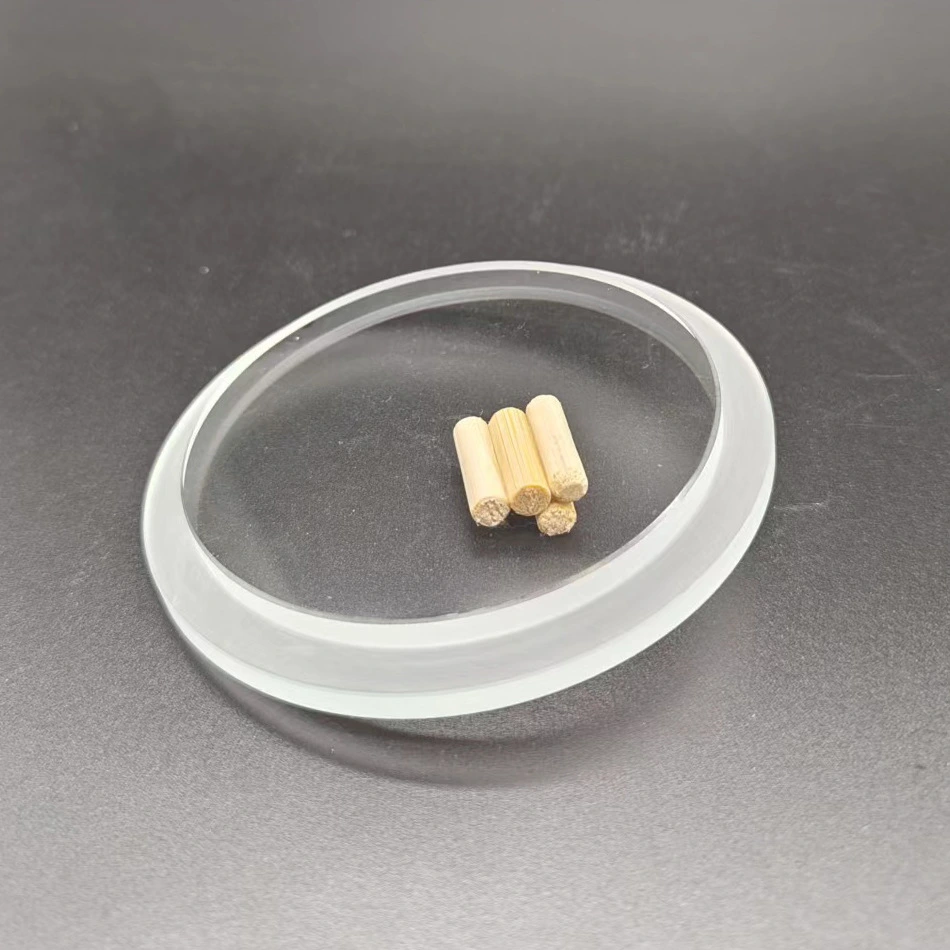

Shenxun knows that every home and client’s needs are different, which is why we can customize our services. Our team of professionals can create the best solution for you. We are committed to providing our customers with glass products and services that exceed expectations.

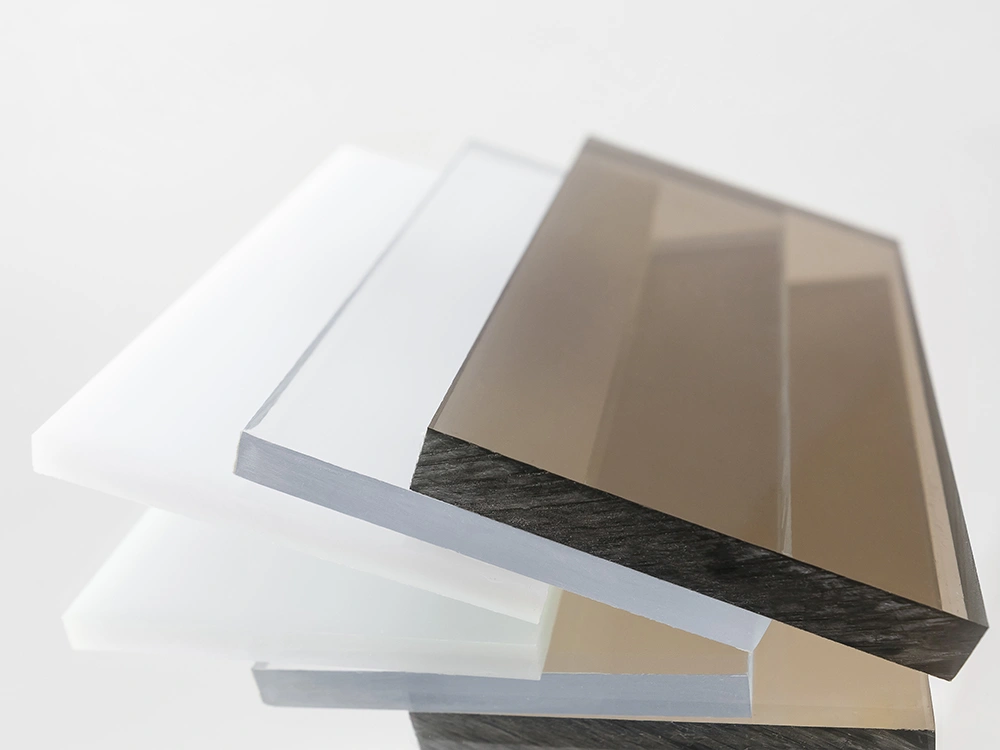

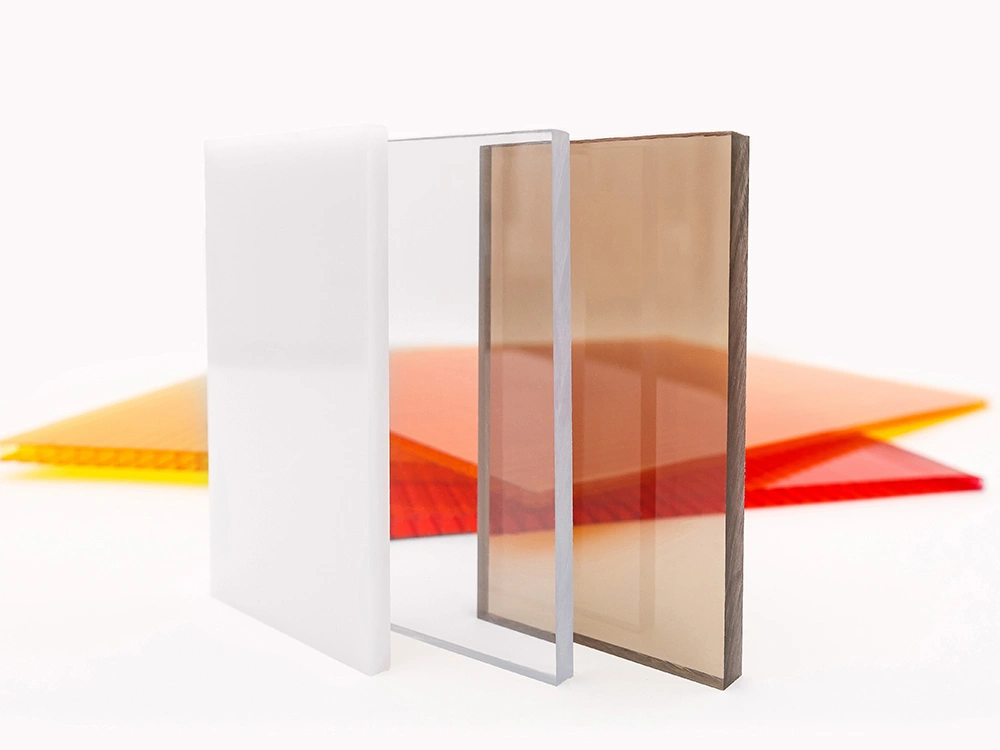

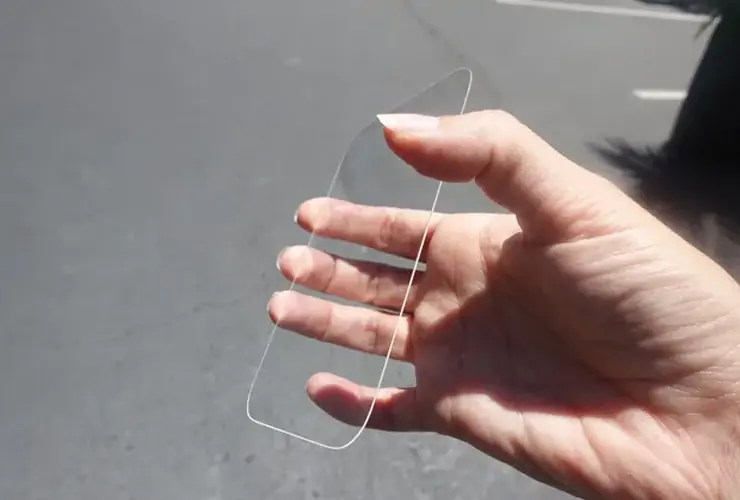

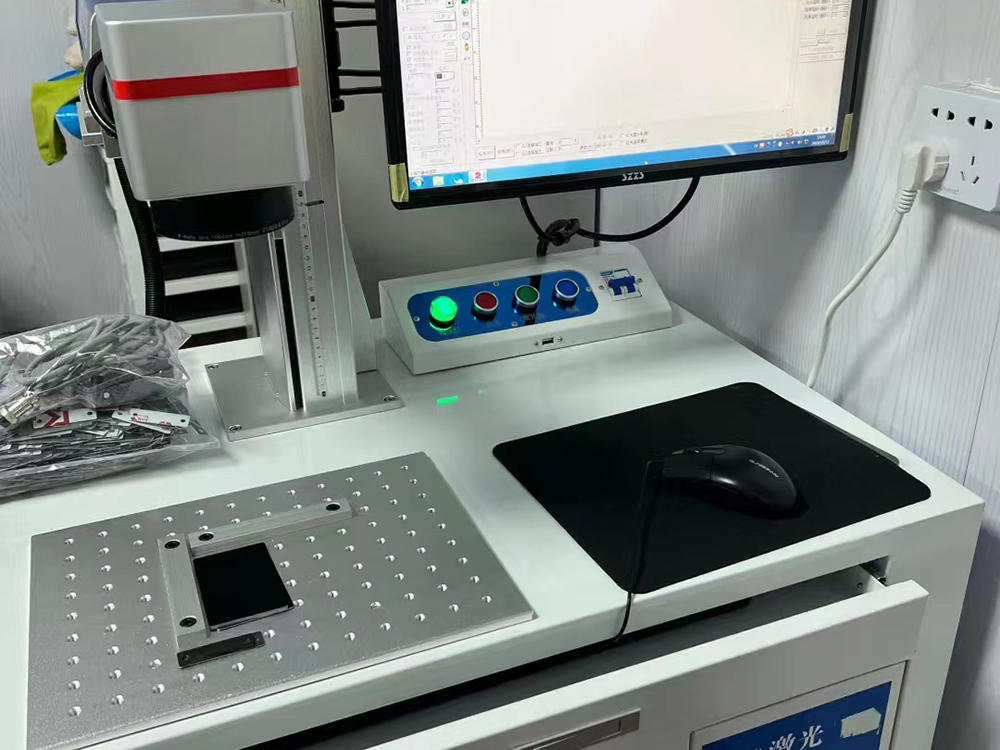

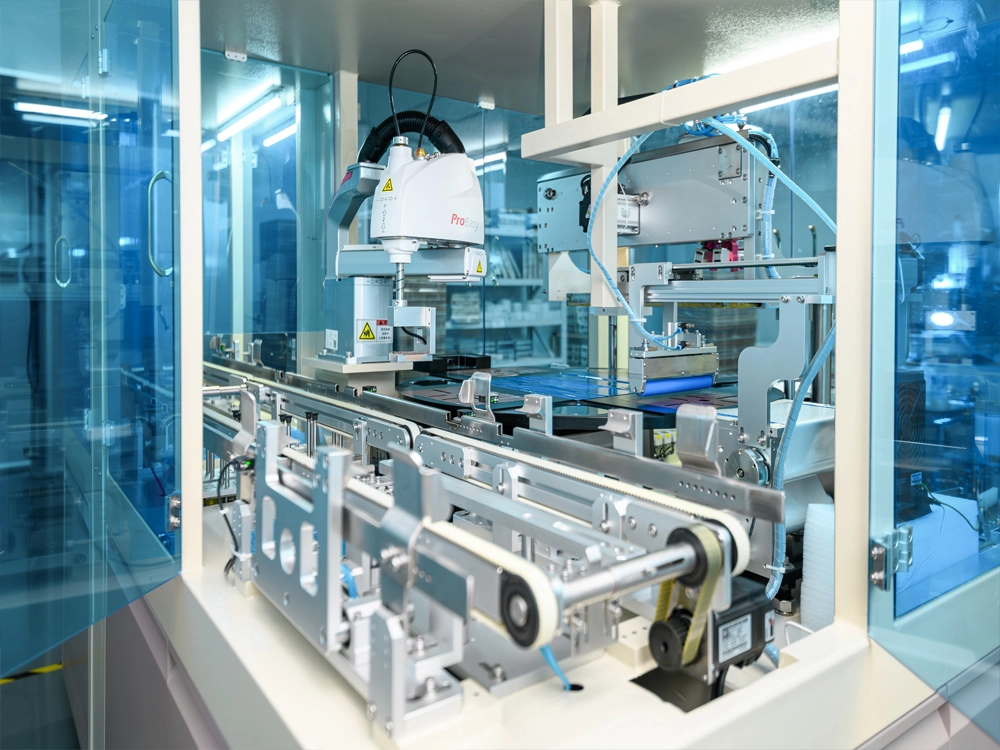

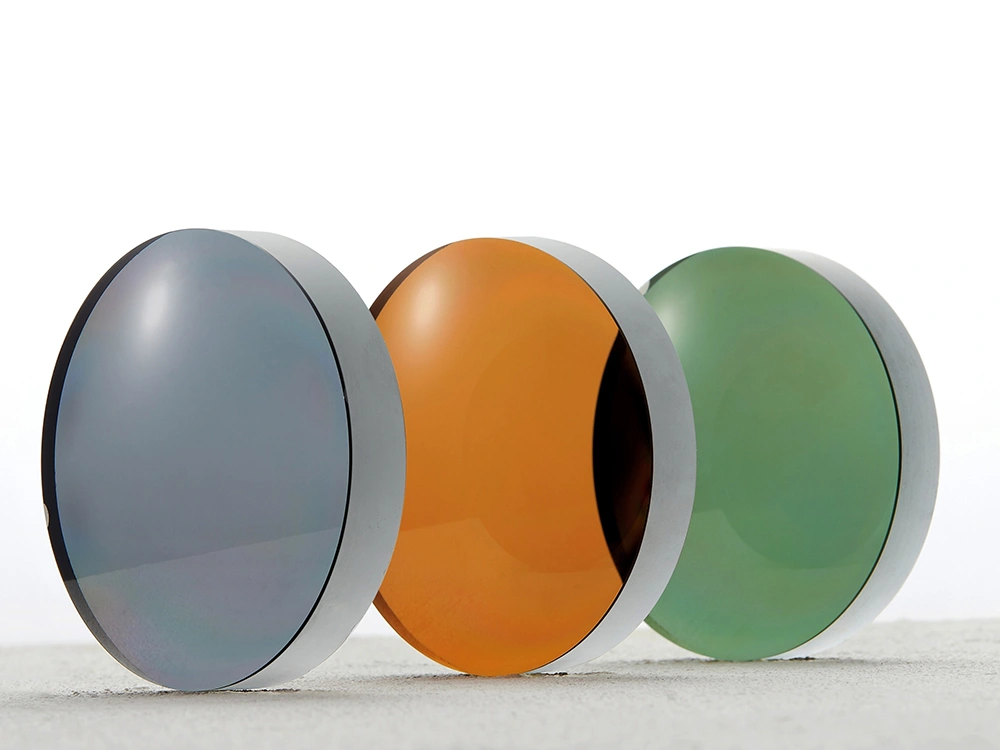

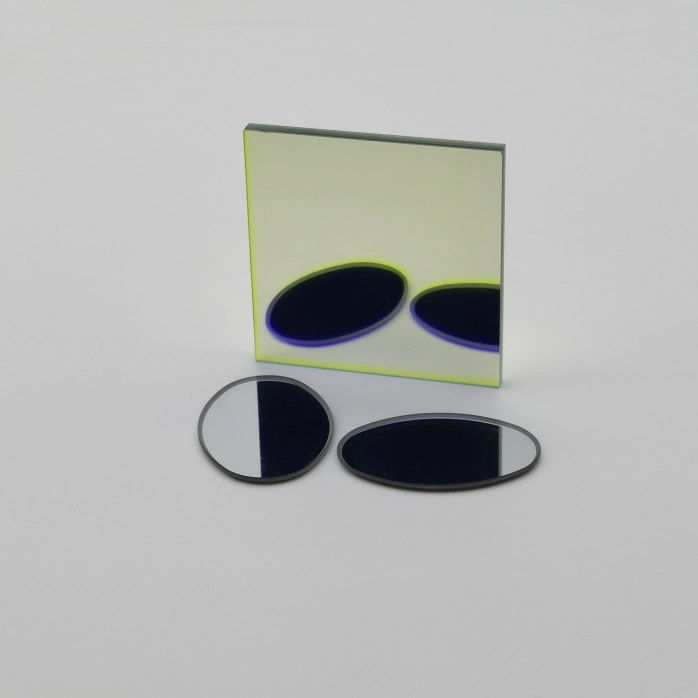

Shenxun’s equipment and technology let us make glass products in many shapes, sizes, and functions. We make high-quality, custom glass products that meet industry standards. Shenxun provides good solutions to our customers.