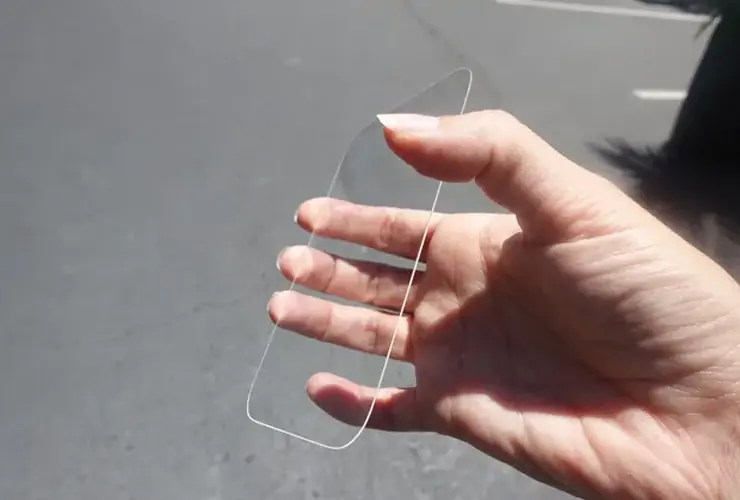

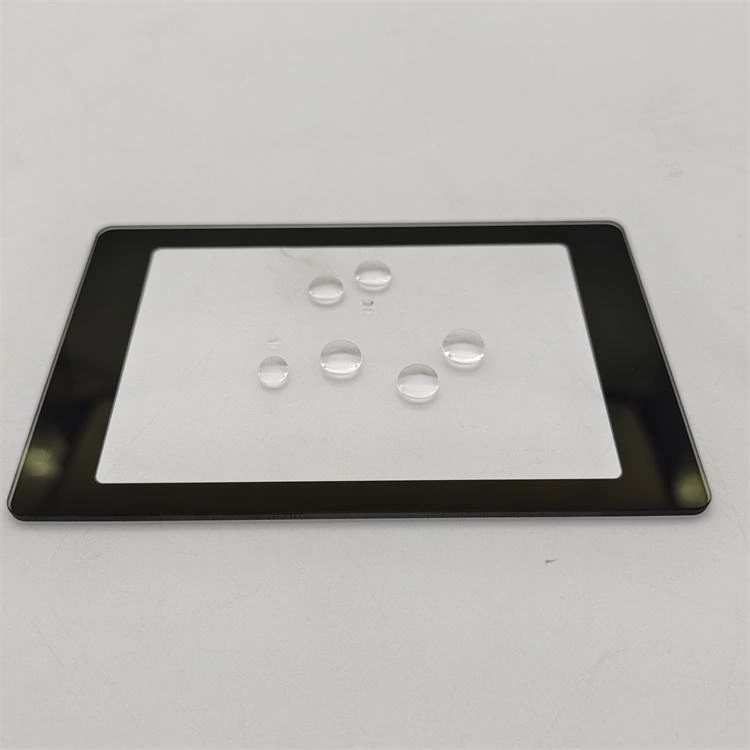

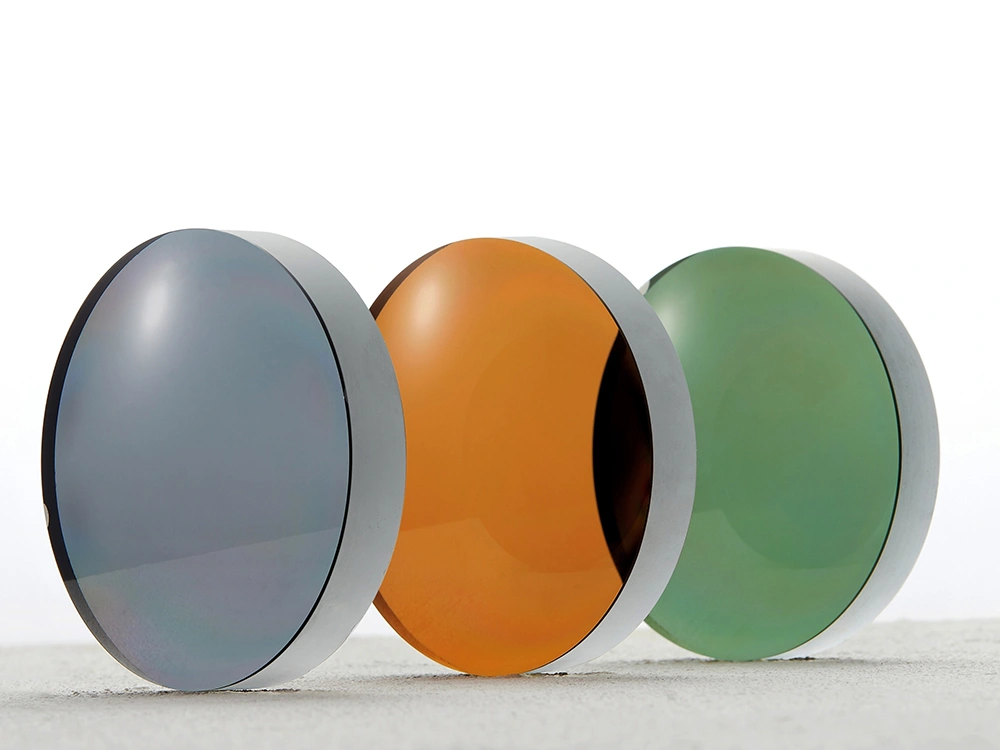

Sapphire glass:

Made of artificial sapphire crystal, it has extremely high hardness and scratch resistance. Commonly used in high-end watch mirrors and screen protection for some smart devices.

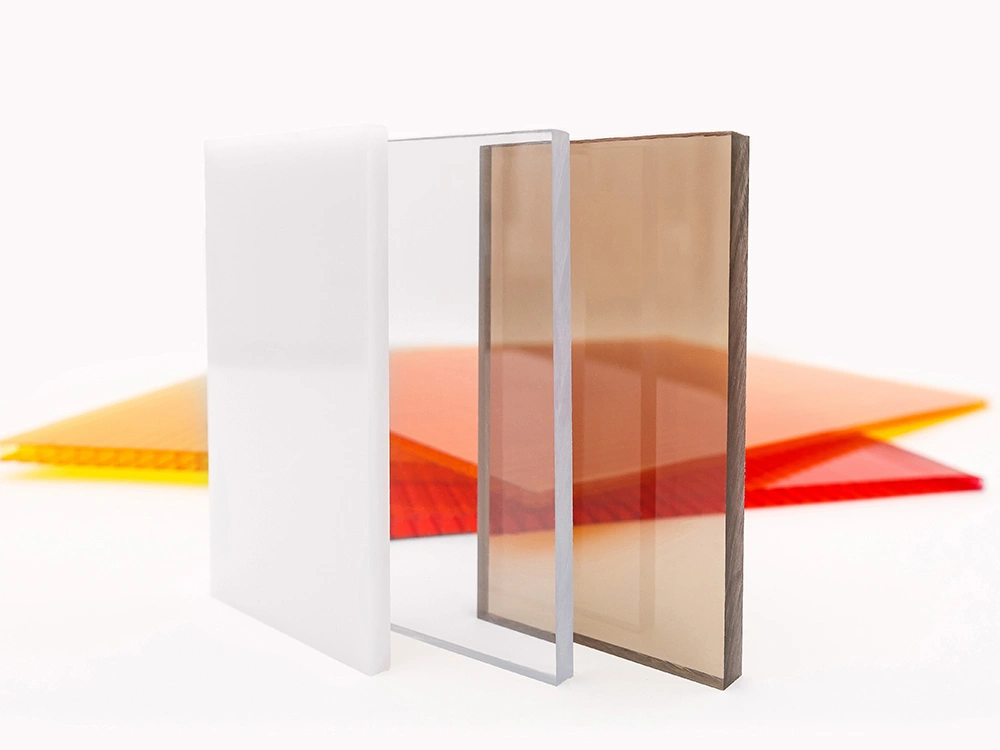

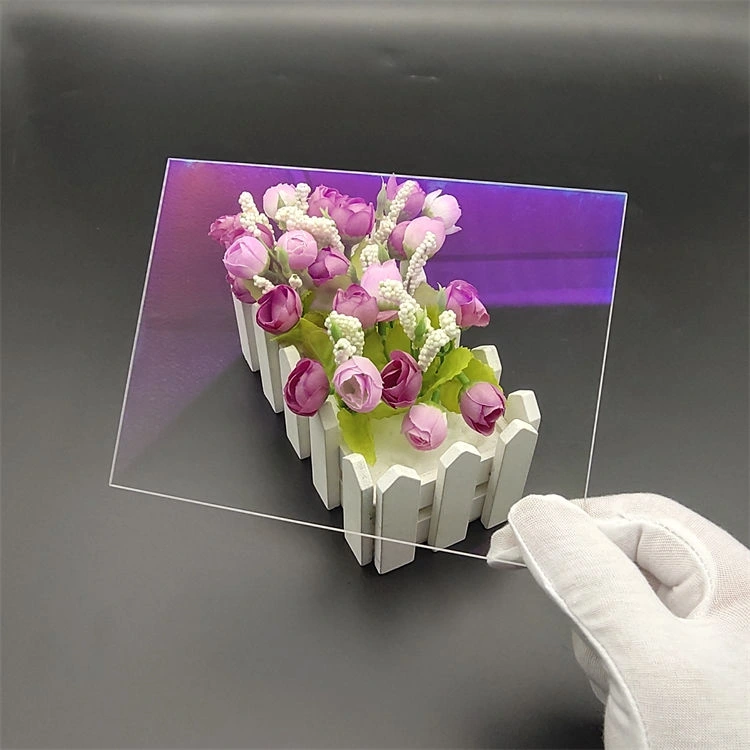

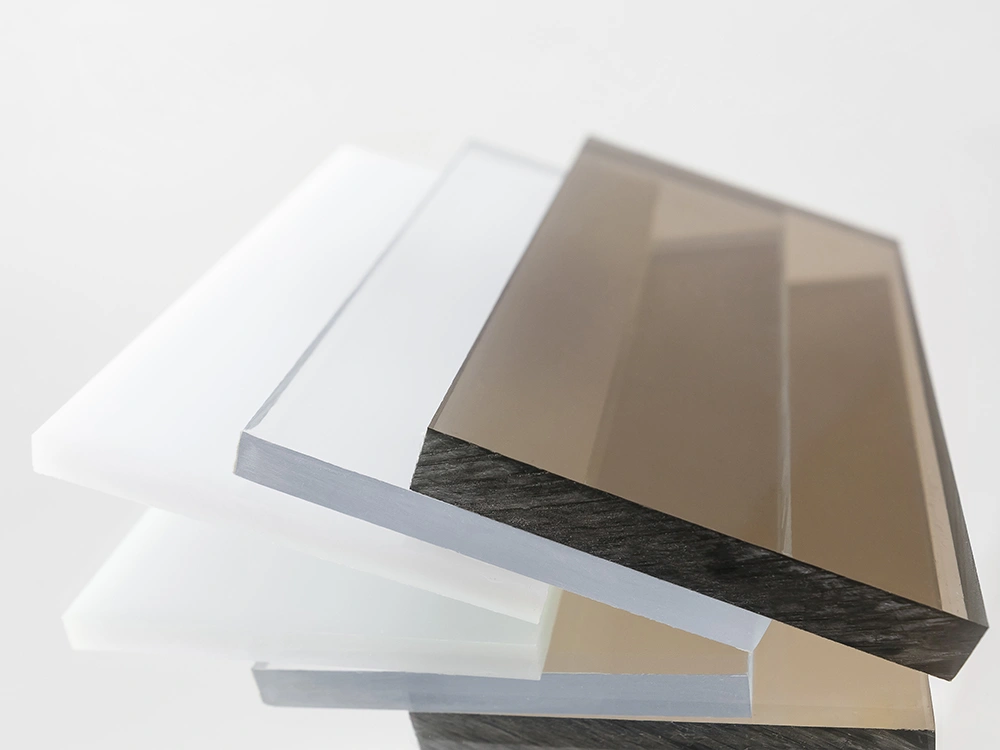

Acrylic glass/PMMA:

Lightweight, highly transparent plastic material with good impact resistance. Widely used in areas such as signs, display cabinets and interior decoration, it is an ideal substitute for glass.