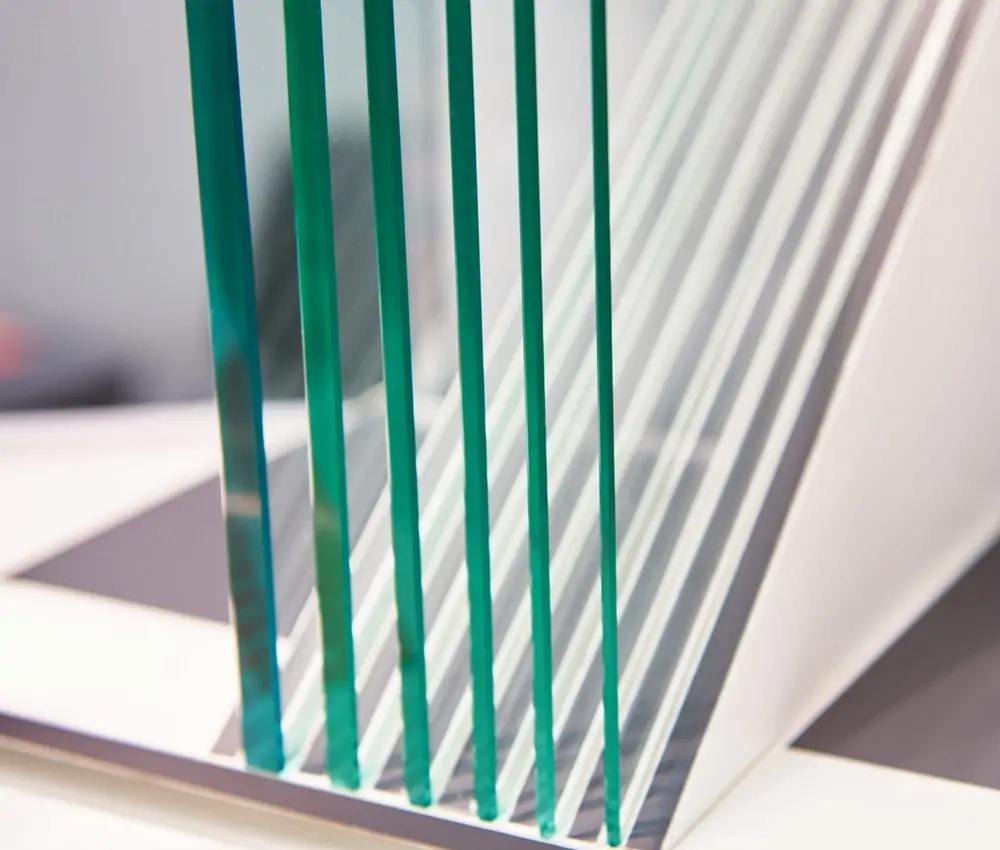

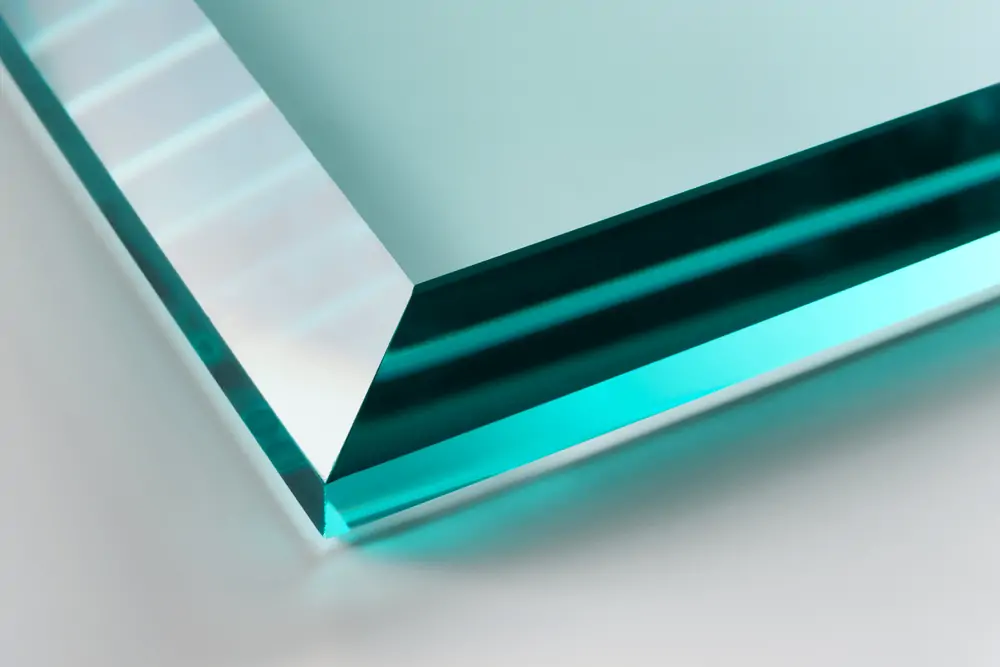

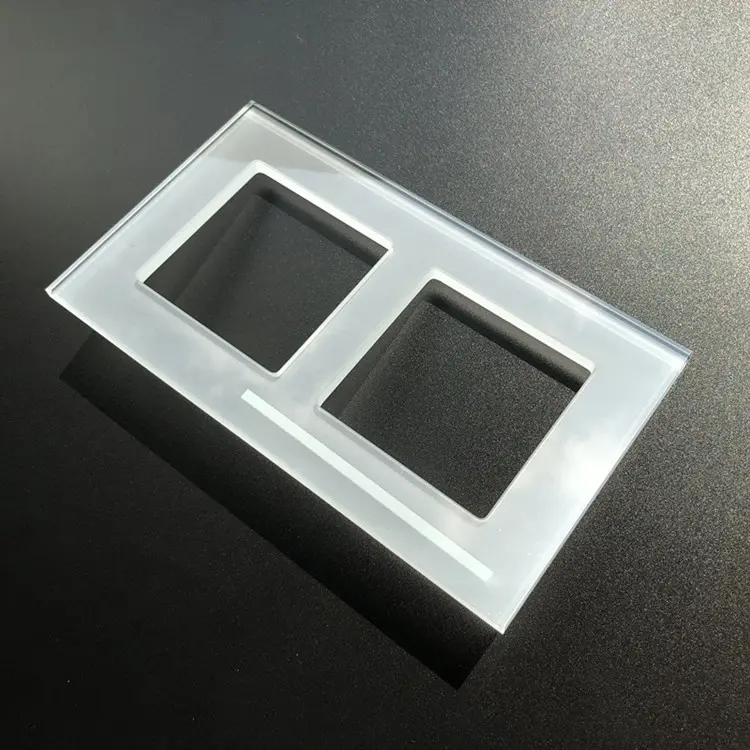

Ultra white glass

High-strength, scratch-resistant specialty glass widely used in smartphone and tablet screens. It has excellent durability and clarity while remaining thin and light.

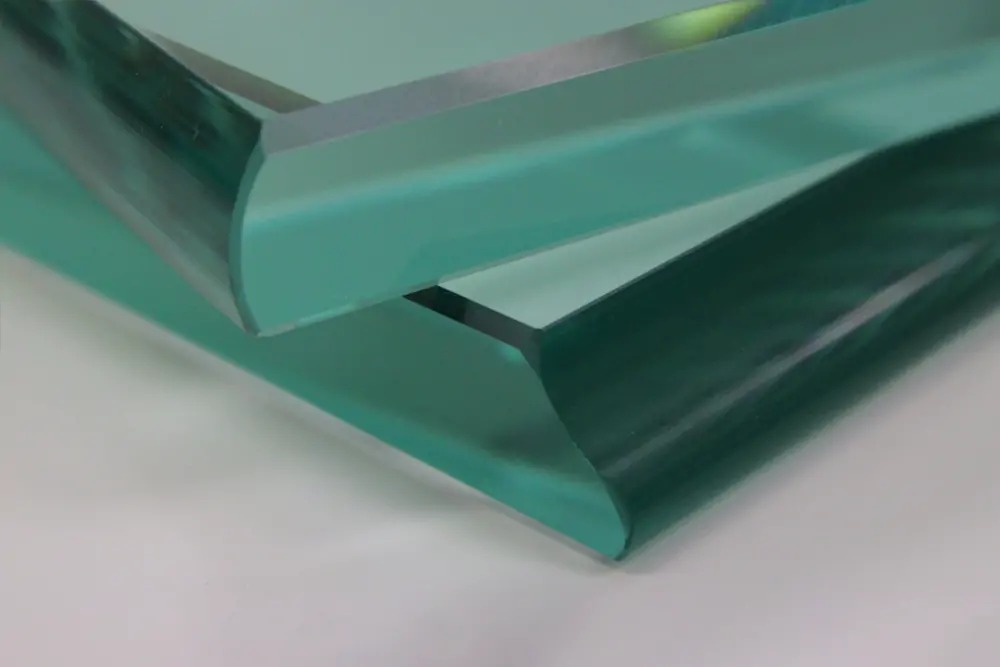

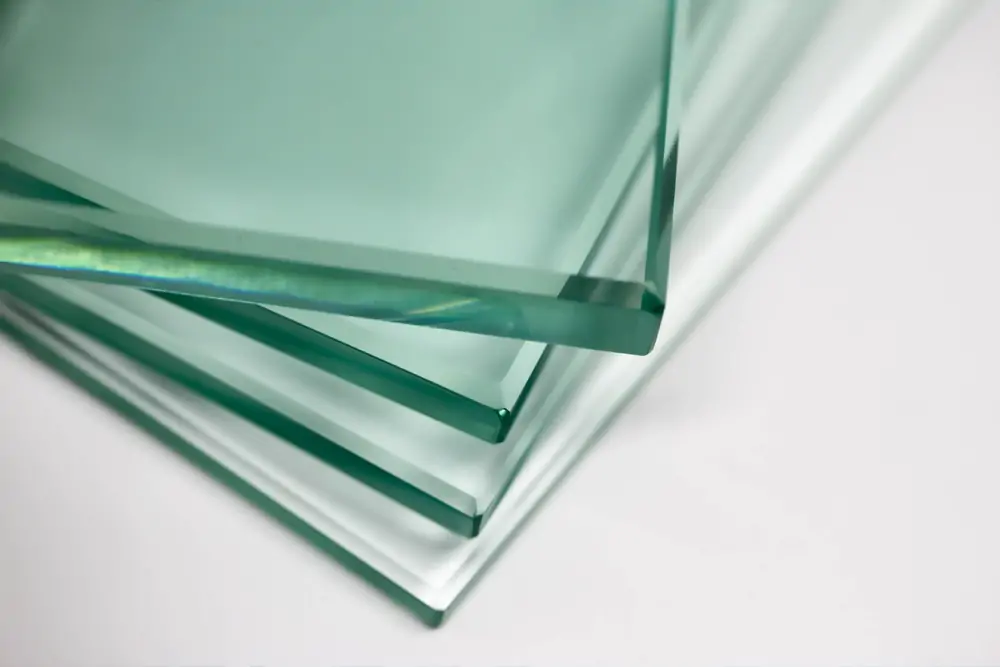

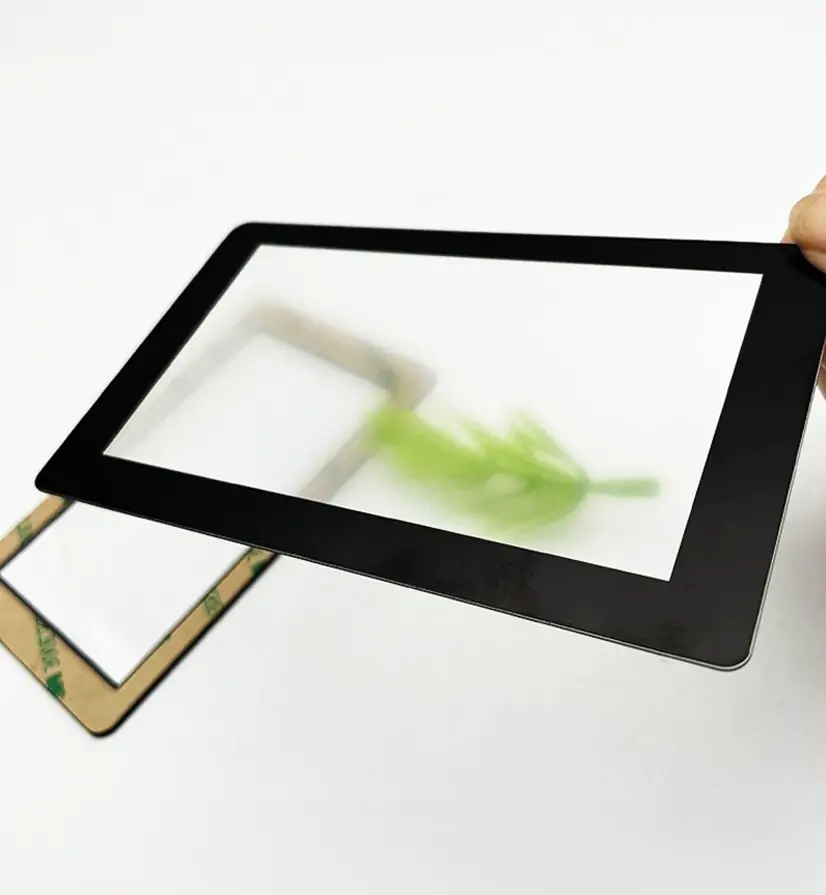

Standard Clear Glass

High-quality glass produced by Asahi Glass for a wide range of applications, from architecture to automobiles. It has excellent optical properties and durability to meet diverse industrial needs.

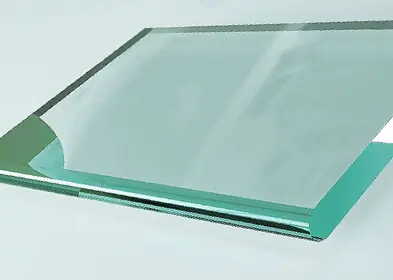

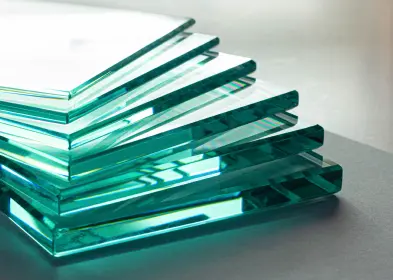

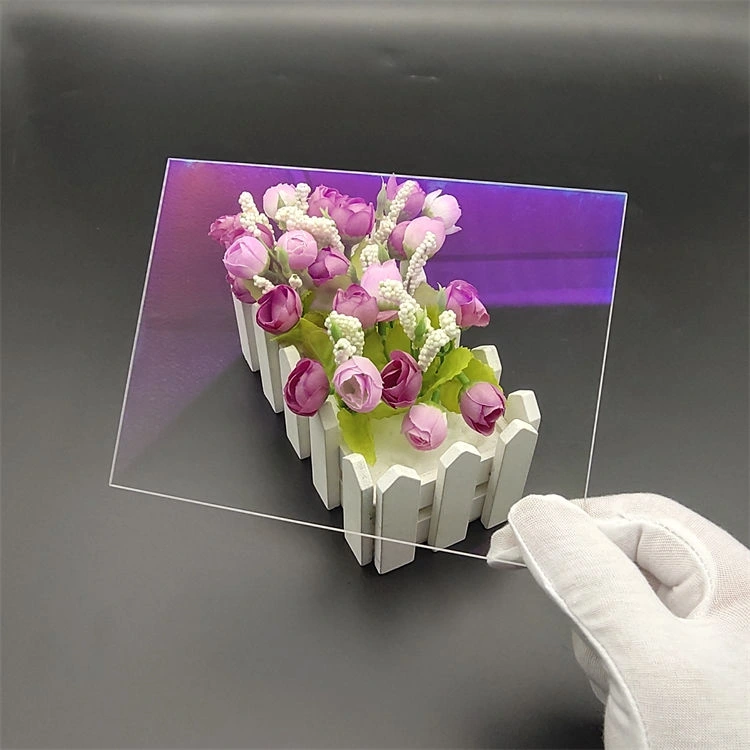

Tinted Glass

High-strength glass designed for mobile devices with excellent drop and scratch resistance. It provides excellent touch and visual clarity for high-end smart devices.