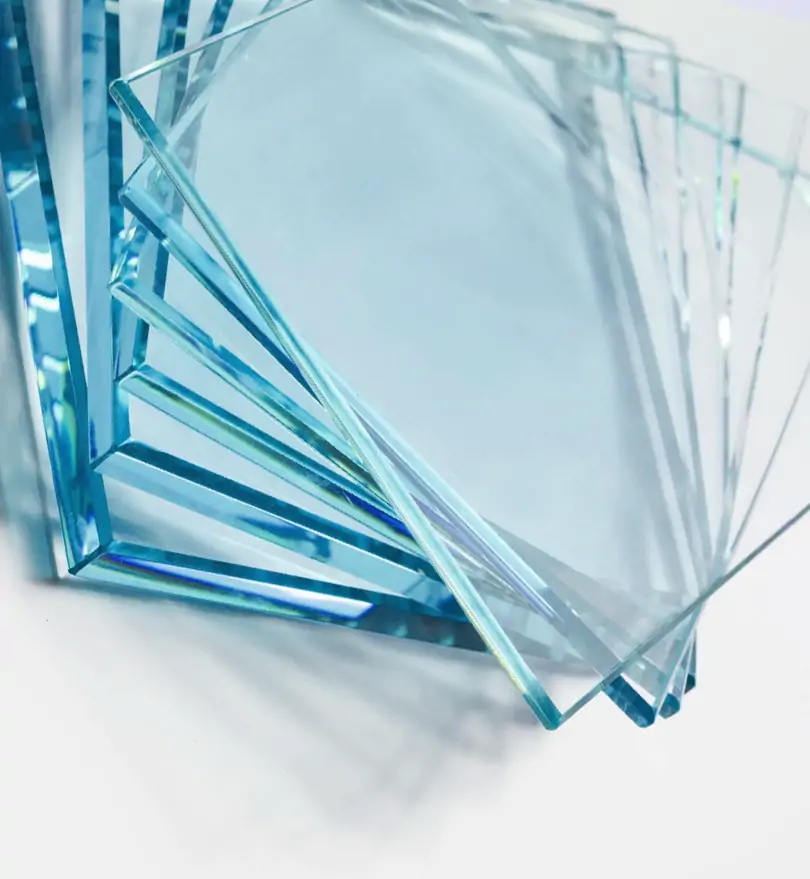

Custom Glass Waterjet Cutting Service

Precision Solutions for All Your Glass Processing Needs

Shenxun Glass is dedicated to providing superior glass-cutting and waterjet-cutting services. We can achieve high precision and efficient cutting with top equipment and technology. We provide the best solutions for all industrial and commercial uses. Our team is experienced and skilled. We will make sure that every project meets our customers’ expectations.

Our waterjet cutting services are equally renowned. Waterjet cutting technology utilizes a high-pressure stream of water to cut and handle a wide range of materials. It is greener than traditional methods and avoids heat, keeping materials precise. We can cut many complex shapes and delicate patterns to meet the needs of different uses.

Choose Shenxun. You will get pro, trusty, and fast glass-cutting and waterjet-cutting.

Get a quote

Waterjet cutting is very accurate. The tolerance range is ±0.50 mm, ensuring a smooth cutting edge.

No heat is generated during waterjet cutting, so the material remains unchanged.

Waterjet cutting uses water and abrasives. It has no chemicals and is free of smoke and dust.

Waterjet cutting has a narrow kerf and less waste. It can maximize the material use.

Waterjet cutting makes it easy to cut complex shapes. It is for a variety of custom designs.

Waterjet cutting is fast. It can shorten production times and boost efficiency.

Shenxun’s glass waterjet cutting is excellent and accurate. Our cutting equipment uses a jet stream that can cut any shape up to 0.01 mm. Our glass waterjet cutting equipment also has these features:

Waterjet cutting glass is efficient and precise. It uses high-pressure water and abrasives to cut glass without making heat. Here is how waterjet cutting glass works precisely:

| Specification | Details |

|---|---|

| Cutting Type | Cut Outs, Holes, Shapes, Complex Shapes |

| Cut Tolerances | 0.50 mm [0.020″] |

| Maximum Thickness | 38.1 mm [1.500″] |

| Minimum Thickness | 1.00 mm [0.040″] |

| Minimum Size | 51 mm x 51 mm [2″ x 2″] |

| Maximum Size | 2,286 mm x 1,168 mm [90″ x 46″] |

| Precision Tolerance | +/- 0.01 inch |

| Material Options | Taped, Coated, Etched Surfaces |

| Software Integration | CAD-compatible for Efficient and Seamless Drawing Integration |

| Industry Versatility | Broad Range of Industries |

| High Pressure Accuracy | Ensures pinpoint accuracy for cutting notches and holes, eliminating distortion or damage |

At Shenxun, we offer many advanced glass-cutting processes. We meet the varied needs of our customers. Below are the primary cutting techniques we utilize:

Waterjet cutting is ideal for manufacturing aerospace components.

It is used to cut circuit boards, touchscreens, and protective glass.

It is used to make decorations like glass doors, mirrors and walls.

It can cut windows, windshields, sunroofs and other automotive glass.

What our customers say

Shenxun’s excellent services are available all over the world. Earning us 100% customer satisfaction.