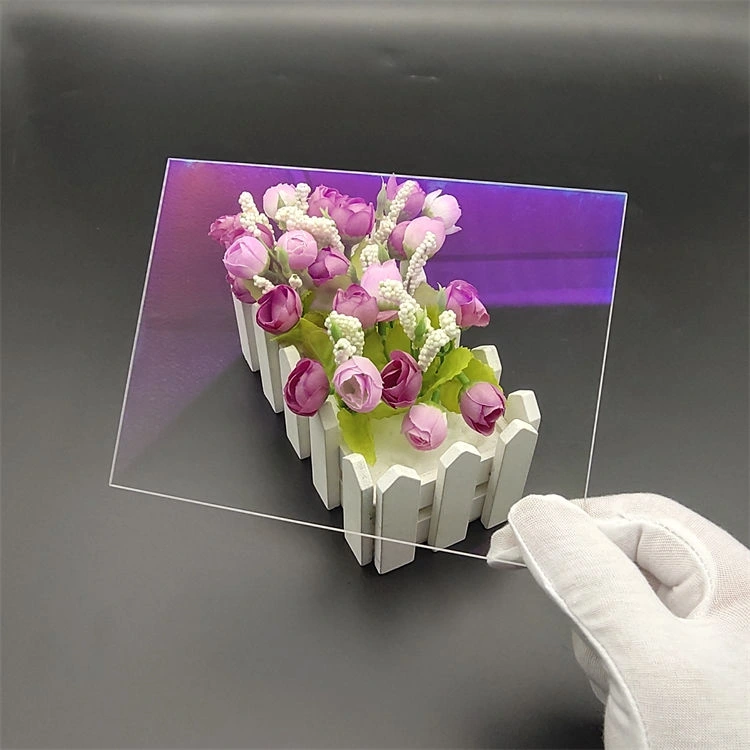

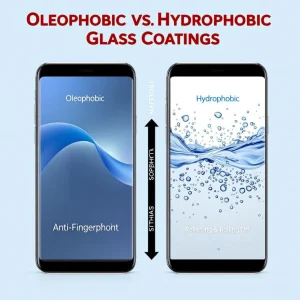

Transmittance:

Non-glare glass usually has high transmittance. It is usually above 90%, ensuring good transparency.

Reflectivity:

Non-glare glass has a low reflectivity, usually below 3%. This reduces glare and reflection.

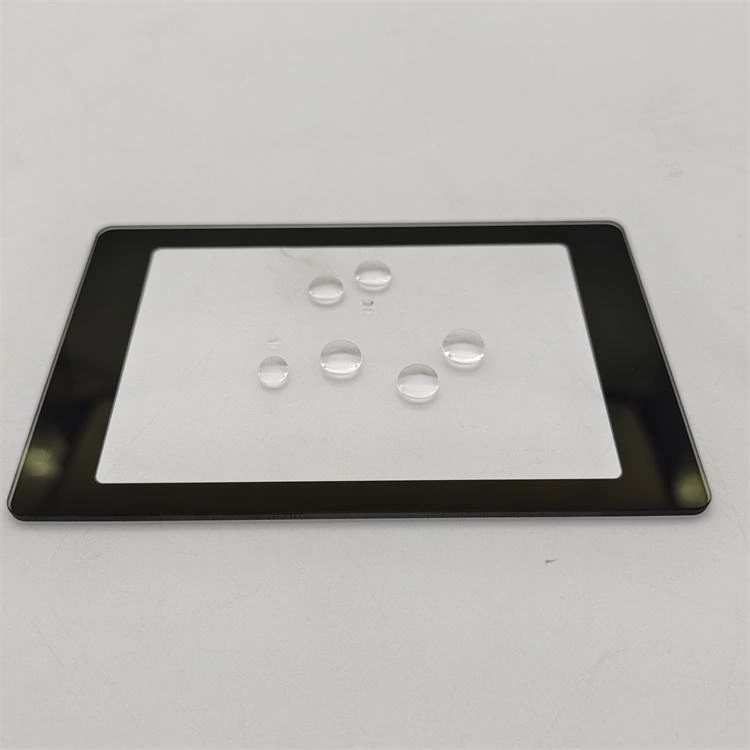

Surface Hardness:

Non-glare glass can be made more complex through chemistry or physics. Expected hardness levels range from 6H to 7H. They provide reasonable protection against scratches.

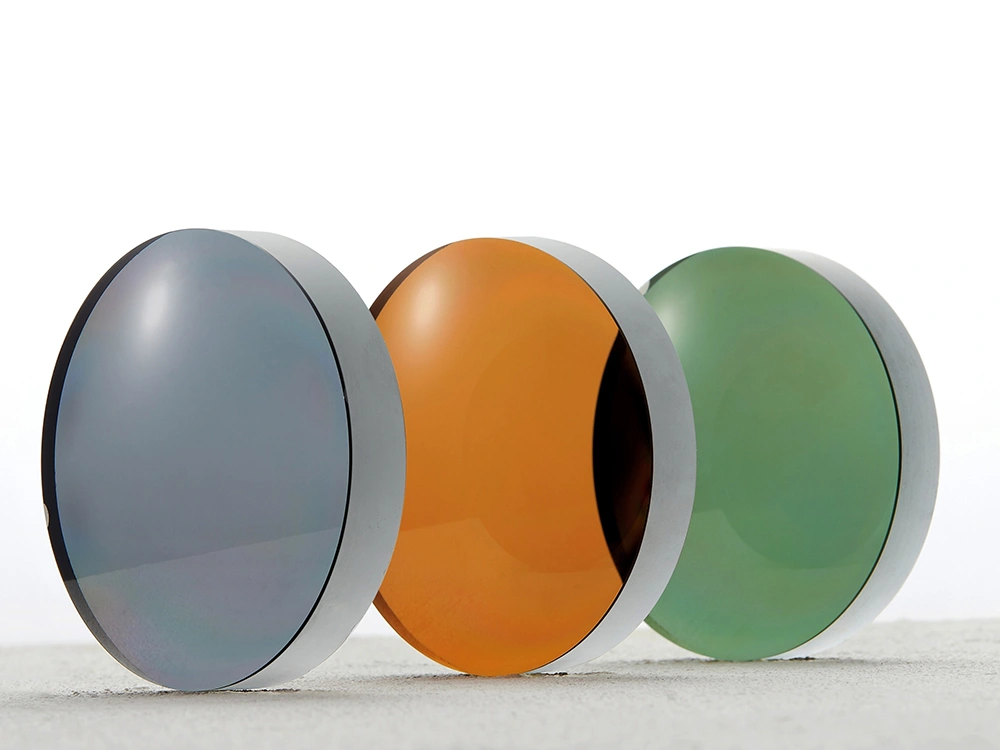

UV blocking:

It can block most of the UV rays, usually over 99%. This protects the objects behind it from UV damage.

Resistance to environmental impacts:

Non-glare glass is resistant to temperature and humidity and lasts well in different weather.

Chemical Resistance:

Resistant to common chemicals, suitable for laboratories, industry, and the outdoors.