Glass Tempering & Glass Heat Strengthening

Customized solutions for increased strength and safety

Shenxun is a glass manufacturer with twenty years of experience. We can provide top-notch glass-strengthening services. We offer Glass Chemical Strengthening. We also offer Glass Tempering and Glass Heat Strengthening.

Tempering glass makes it much more robust and impact-resistant. It does this by quickly heating and cooling the glass, creating compressive stress on the surface and tensile stress inside. Our glass tempering products are used in many areas, such as automobiles and household appliances. They give customers excellent safety and durability.

Glass Heat Strengthening is like glass tempering, but the cooling rate is slightly slower. This results in slightly lower compressive stresses and strength. Still, heat-strengthening glass is great. It boosts the glass’s strength and resistance to heat.

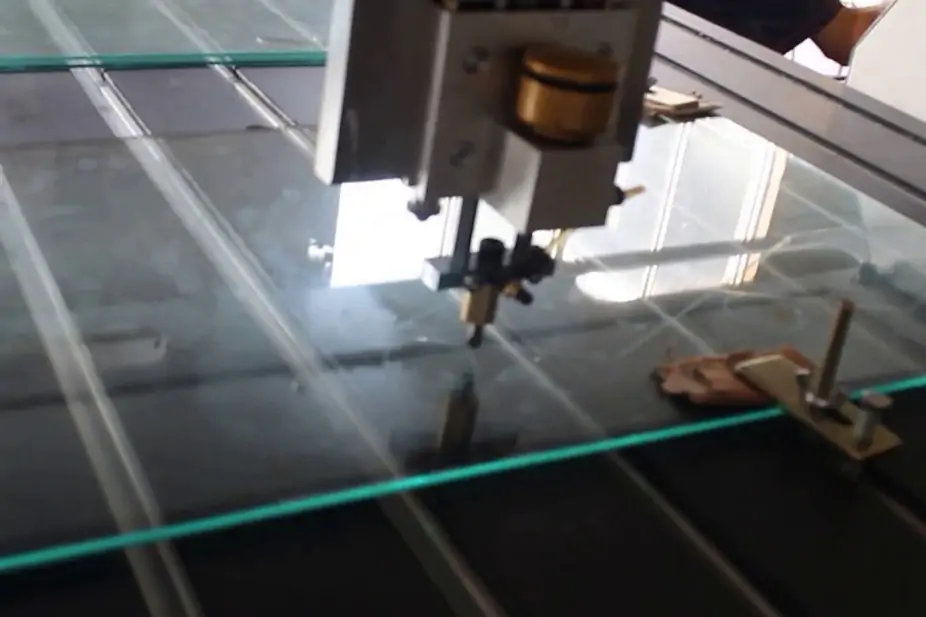

Get a quoteGlass toughening is a process that physically increases the strength and safety of glass. The glass is first heated near its softening point, usually between 620°C and 650°C. Then, it is quickly air-cooled. The rapid cooling creates intense compressive stress on the glass’s surface and tensile stress inside. This makes the glass four to five times stronger than standard annealed glass.

Glass tempering offers significant safety advantages. When tempered glass breaks, it forms small, blunt, granular fragments that are not sharp. It greatly reduces the risk of injury to the body. It makes tempered glass the top choice for high safety requirements. These include automotive windshields, architectural curtain walls, windows, and doors.

Glass toughening makes glass 4-5 times stronger than ordinary glass. It can withstand greater forces and impacts, improving its durability.

Tempered glass will form small, blunt fragments when broken. This is much safer than sharp fragments. It greatly reduces the risk of injury to the body.

Tempered glass can handle significant temperature changes and is not easily broken by temperature, making it suitable for high-heat applications.

Tempered glass is much better at resisting bending. It suits applications requiring high mechanical stress.

Tempered glass is solid and safe. It is widely used to meet high standards in many fields, such as architecture, cars, and home goods.

Tempered glass has excellent optics. It is highly transparent and smooth, and it can enhance the class and look of the design.

Thermal strengthening is a process that makes the glass stronger. Heat strengthening is like glass tempering. It creates surface compressive and internal tensile stresses by heating and cooling the glass. But, the cooling is slower. First, the glass is heated close to its softening point and then cooled slowly. This slow cooling process creates moderate compressive stresses on the surface of the glass. It also produces small tensile stresses inside. These stresses make the glass stronger.

Heat-strengthened glass is different from tempered glass. When it breaks, it forms larger, obtuse fragments rather than small, granular ones. This breakage characteristic isn’t as safe as tempered glass, but it still reduces the risk of injury in many uses. Thermally strengthened glass is for applications that need high strength. But, it may require less safety.

Heat-strengthened glass makes the glass 2-3 times stronger than ordinary glass. It can withstand greater forces and impacts, making it much more durable.

When broken, heat-strengthened glass forms larger, obtuse fragments, reducing the risk of injury to the human body.

Heat-strengthened glass is heat-resistant and can withstand high temperatures. It prevents glass from breaking due to temperature changes.

Heat-strengthened glass has much better bending resistance. This makes it suitable for applications that need to handle stress.

Heat-strengthened glass is widely used in high-rise building facades and solar panels. It is also used in transportation facilities and safety glass in public places. It meets the needs of different occasions.

Heat-toughened glass is more economical than tempered glass in some cases. It improves strength and controls costs.

At Shenxun, we offer custom glass tempering and strengthening services. We tailor them to meet specific uses and quality standards.

We can customize many glass sizes and shapes to match customer drawings and specs, allowing us to meet the needs of different uses.

Heat treatment parameter optimization:

We adjust heating and cooling times and temperatures based on glass thickness, type, and usage. Glass tempering uses fast cooling, and glass heat strengthening uses slow cooling. Both processes ensure the glass has optimal strength and safety.

What our customers say

Shenxun’s excellent services are available all over the world. Earning us 100% customer satisfaction.