If you work in the home decor industry, the aesthetic of the windows is as important as the home itself. From glass railings quality to matching colors, all play out crucially.

Don’t miss the magic of the glass edges that provide an immersive look from a far view. But what type of edge work do you need?

There are different types of glass edge finishes.

As a pro selector, you must hunt down the quality and appearance and opt for the best. Today, we will discuss the various types of edges and add relevant applications.

What is a glass edge finish?

The glass edge is the end of the glass sheet that can be sharp, smooth, or shaped into a specific pattern. The exposed part features an elegant look and provides an external glamor to the material.

Glass edge finish refers to the customization of the glass edges. For example, grinding the sharp edges can produce a smooth and clean edge. The finish can be customized per the customer’s needs and provides an excellent texture to the overall glass sheet.

Why should you consider a glass edge finish?

The glass looks elegant because of its components, such as its surface and edges. A sharp edge can also be dangerous for users and might require special handling. From safety to customization, there are a few aspects to consider for your glass edge finishes.

-

Safety

Do you think a sharp edge causes injury? Don’t worry; mold it into another shape. Say thanks to the glass edge finish services that offer this opportunity.

A well-finished glass edge can appear great and provide a smooth look. It keeps the injury miles away when handling and provides an excellent look. Moreover, handling is effortless and provides a fantastic experience for consumers.

-

Aesthetic Appeal

It is less likely that many applications need rough glass edges. Instead, you can explore tons of applications requiring aesthetic appeal. Many decorative pieces need a well-finished glass edge that is safe to handle and easy to deploy.

The sleek appearance of the glass edges makes it a perfect choice for frames, mirrors, and furniture products.

-

Durability

You might wonder, but it is 100% true that the safety of the glass materials is elevated with the glass edge finish. For instance, when applied, the rounded edge is stronger and absorbs more force. Therefore, the risks of damage and cracks are less likely to appear on the surface.

You can avoid the cracking, chipping, or breakage of the glass materials over an extended period. This enhanced durability of the glass material is crucial for its use in high-traffic areas.

-

Functionality

Standalone glass applications are widespread. However, there is no hidden fact that combining two glass pieces is quite effective. When combining two glass pieces, the first thing that comes to mind is their fittings into their counterparts.

It relies on the edge finishes. The sharp edges might fit tightly with a sharp edge. Similarly, a polished round edge is impressive for its tight fitting in various applications.

-

Customization

Glass customization has built-in edge customization to form a combo of aesthetic appeal. However, the polished edges provide a better look and effective combination.

Their full-fledged customization bestows a new life on customers. You can get the desired performance and look from your customized glass edge finishes.

Common Glass Edge Finish Types

Glass edge finishes include multiple types. From simple and flat edges to pencil-like smoothness, you can dig out various edges. Let’s explore the famous edges of numerous applications.

-

Pencil-Polished Edge

The pencil-polished edge is smooth and grounded to make it more elegant. The C-shape edge curve with the smooth surface makes it preferable for decorative applications.

The glossy appearance is due to classic pencil edges that outshine all other patterns. The accuracy in the edge finishes is crucial for such materials.

This material has pencil-shaped edges, so it is named after it. The typical applications include furniture and glass displays.

- Furniture

- Mirrors

- Frames

- Shelves

- Display Cases

-

Pencil Satin Edge

Do you want to further boost the appearance of your pencil edge types? The pencil satin edge has a satin-like sheen and creates an impact in the light color applications. The better outlook and excellent shape make it the first choice for transparent surfaces.

The following are the applications of pencil satin edge type.

- Light-Color Surfaces

- Mirrors

- Decorative Glass Furniture

-

Flat-Polished Edge

Flat polished edge is another glass marvel featuring an elegant look. The cutting of glass edges and polishing them provides a sleek finish. The 45-degree chamfering of edges with the glass surface removes the finish and provides a glossy appearance.

Manufacturers need high-quality machines to make and polish such glass edges for an excellent look. Moreover, this edge type appears thicker on the external view.

The standard applications of this flat polished edge include:

- Mirrors

- Retail Display Cases

- Glass Dividers & Partitions

- Decorative Furniture

-

Flat Satin

Welcome another decorative glass edge that engages the users with its glossy appearance. It is similar to the structure’s pencil satin edge but has a flat appearance. Moreover, it is beneficial for the mirror for decorative applications by nurturing an elegant look with a classy finish.

- Mirrors

- Decorative Glass Furniture

-

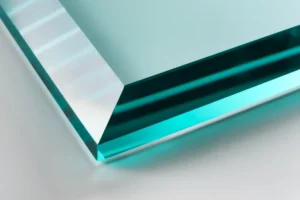

Beveled Edge

The beveled edges of the glass materials are pretty famous for their elegance and excellent finish. The grinding of the sharp edges and smooth surface provides an astonishing look. The chamfered top and bottom of the glass edges make it suitable for decorative applications.

Such glass materials are thicker in the middle while thinner at the edges. Wondering why? Because of grinding applications. The shiny look gives a next-level finish to this glass material.

- Mirrors

- Other Decorative Glass Solutions

-

Miter Edge

Miter Edge has a beveling at 60 degrees and can stand out as a single glass piece. The glass’s high-strength thickness allows it to be placed in various applications, such as retail display glasses.

The beveling at 60 degrees provides a differentiated look when two glass materials are conjoined.

- Retail Display Cases

- Glass Shelving

- Any Setting Requiring Thick Glass

-

Seamed Edge

A seamed edge is a popular choice for glass fabricators. However, it is not beneficial for decorative applications requiring an excellent finish. Seamed edges have a flat surface but with sanded edges. A sanding belt helps remove sharp edges. Therefore, this glass type is a famous choice for the various applications related to framed walls.

The quick overview of applications deploying seamed edges include:

- Framed Glass Walls & Partitions

- Non-Decorative Solution

What should you consider when choosing a glass edge finish type?

It is challenging to opt for one glass edge finish type and ignore the other. Each type has an excellent view and fits many applications. If you are confused about the selection, relax! We have added the tips for selecting the suitable glass edge finish type.

-

Purpose and Application

The intended use of the glass is a deciding factor. For example, tabletop glasses require a more refined finish than construction applications. Measure the overall exposure of different edges of the glass materials. More exposed applications require a sophisticated edge for better safety and durability.

-

Aesthetic Preference

Edge finish is a significant factor in deciding the overall look of your glass. Flat edges seem good but do not fit every application. For industrial applications, go for flat or miter edge finishes. On the other hand, a sleek design can be an ideal choice for a modern look.

Compare the designs of different materials and match them with the required glass application. Choose an elegant style with a premium quality edge.

-

Safety

Safety is the priority in areas where you must interact with the glass. Sharp edges can cut through the skin. Compared to it, round and pencil edges are a safer choice. Based on your safety needs, compare the features of different glass finish types. For better choices, you can opt for the different safety tests. Get the results and fetch a seamless experience for better edge finishes.

-

Durability

Having an extended use of materials is quite common. Consider the durability with the thickness of the material. Some glass edge finishes offer more strength. Top-class finished edges are quick to clean and easy to maintain. On the other hand, some edge types don’t match the standard durability. Think about the material quality and relevant crack-to-scratch resistance.

-

Cost

Polished and beveled edges are expensive and a choice for high-quality glass applications. However, flat to round edges are affordable. Before opting for the edge finishes, consider:

- Budget

- Quality

- Relevant compatibility

If the edge meets your standards and comes with built-in quality and affordable pricing, adopt it! Otherwise, look for newer and affordable options that meet your demands.

Conclusion

Do you want a customized glass edge? Find it with the top glass fabricators. Dive into the market and find out who the best glass manufacturer is.

Shenxun Glass Manufacturers are talk-of-the-town. Wondering why? Because of full-fledged customization and affordability. Plus, you get the quality assurance for all your glass materials. Talk to the experts right away!