Finding quality glass at different stores is quite common. At times, you might have wondered about the quality of the glass and its specifications. You might even need to customize your glass to fit your needs.

Is that so? Well, that is where you must explore options like Glass Fabrication. It provides a full-fledged customization opportunity and enhances your ease of glass manufacturing.

Today, we will dive deep into the fabrication process and write different methods with benefits.

What is Glass Fabrication?

Glass Fabrication is an extensive process that includes cutting and shaping the glass materials.

It might include numerous customization processes. For example:

- Cutting

- Shaping

- Grinding

- Drilling

- Polishing

- Tempering

- Laminating

- Finishing

- Edging

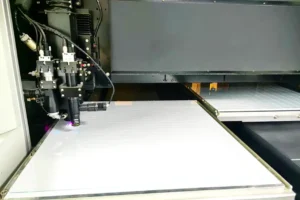

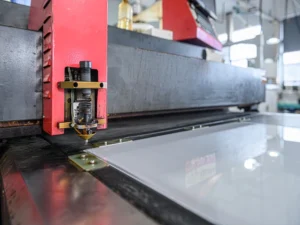

However, the whole fabrication process is nowadays filled with cutting-edge technology solutions. The CNC machines get accurate data about the cutting or shaping. Fabricators ensure precision by deploying such machines all over their glass customization.

Types of Glass Fabrication

Glass fabrication can be of various types. For instance, if the glass vendor cuts and shapes a material, it is the fabrication. However, we have listed some crucial and common types you might have heard about.

-

Custom-Cut Sizes

Observe the railings and reception windows. The specific installation cuts and holes bow down the particular equipment available to the glass vendors. They come with the accurate cutting of different sizes.

CNC machines get precise input about the angles, cutting parts, and relevant features. Finally, the hit at the glass materials validates the easy and best cutting opportunity.

However, some manufacturers have tools that are different from others. Therefore, limitations on different tools can cause the cutting of a limited number of articles.

-

Glass Shaping

Fabrication of the glass materials into specific structures refers to the glass shaping. Advanced manufacturing tools can now transform glass materials into any shape. Enjoy all the custom shapes and designs on priority whether you want square-shaped glass or rectangular.

The common fabricated glass types include:

- Squares

- Rectangles

- Triangles

- Trapezoids

- Parallelograms

- Arches

- Irregular gables

- Quarter pie

- Rectangles with radius corners

- Half-circles

Customers can discuss the shapes with the vendors in addition to the above structures and shapes. The ultimate result is deep-down customization to any shape, relying on the availability and precision of the tools.

-

Tempering

If you have been involved more in the glass industry, you might know about glass tempering. It is the process of heating glass at higher temperatures and then cooling rapidly to the desired tempering temperature.

Why do you do so?

The simple and easy logic is to strengthen the glass materials. The compressive stress between the molecules elevates the overall strength.

Not only the strength but also the safety of such tempered glass materials jumps up. It is due to breakage into small pieces less likely to harm humans.

-

Edge Works

When the consumer needs an excellent finish and elegant look with the smoothness of the edges of glass materials, edge fabrication is their favorite option. Manufacturers need the edge finishes’ requirements, shapes, and safety instructions.

The following edges are popular.

- Beveled edge

- Mitred edge

- Flat edge

- Pencil edge

- Bullnose edge

- Ogee edge

- Waterfall

The thickness of the glass materials can impact the edges. You must consider working with the experts for your relevant glass thickness and edges of the materials.

-

V Grooving

V Grooving is a unique tactic in the surface of the glass materials. It adds a peculiar feature to the glass and creates a classy reflection and refraction of the light.

V-shaped lines can be either cut or grooved on the surface. A polished look with a clear finish can elevate the overall look of your glass materials and provide an elegant look.

Different manufacturers and glass vendors have various tools and customization for such a finish.

Benefits of Glass Fabrication

Glass fabrication can be a blessing for consumers looking to customize their glass materials.

A quick look at various benefits is:

-

Customization

Glass fabrication is another name for the different types of glass customization. That means users can specify their dream designs and requirements. Add their inputs into the material fabrication. And finally, grab their favorite designs with an elegant finish.

Tinted, frosted, or various patterns of the glass materials make them suitable for tons of daily glass applications. Even the glass windows look elegant with the effective customization of the material.

-

Elevated strength and durability

Do you know about glass tempering? Heating and rapid cooling of the glass materials can help increase the molecular bonds and strength.

Such a strength is beneficial because:

- Material is less prone to damage. Extensive strength keeps the glass materials in the original condition upon falling from a height.

- It offers a wide range of applications, such as manufacturing display glass.

Moreover, materials like the laminated glass have an additional durability with the multiple layered structure of the glass materials.

Your glass can extend its lifespan and go without damage for many years.

-

Safety

Who doesn’t know the safety of the tempered and laminated glass materials?

Tempered glass is less likely to break until you exceed a specific force limit. Don’t worry, even if it breaks into pieces. They are so small and won’t cause damage to your skin parts.

Moreover, laminated glass is impenetrable due to the durability of the plastic layer. It creates an excellent barrier with improved durability of the materials.

-

Energy Efficiency

Fabrication of the glass materials makes it an excellent insulator. The introduction of insulated glass units (IGUs) has revolutionized the energy game. They comprise the gas-filled spaces that reduce the energy transfer and keep the internal temperature under control. So consumers don’t have to waste energy anymore.

Low-emissivity (Low-E) Coatings have further helped in the temperature insulation. They don’t let the heat or cold escape from the building’s glass materials.

The result is improved energy efficiency with excellent insulation ideas.

-

Aesthetic Appeal

Glass fabrication creates a matchless blend of beauty and strength. Decorative glass pieces have dominated due to their aesthetic appeal.

Fabrication techniques like etching, sandblasting, or acid washing make a perfect glass material for your decorative materials. The awesome surface finish allows the usage of glass in interior design to architectural applications.

The ability to alter the design and shape with the light reflection and refraction allows an impactful deal at this point. Users can create an aesthetic appeal of their materials.

Applications of Glass Fabrication

Glass fabrication hasn’t only boosted architectural applications and opened doors for manipulative options.

The details of different applications of glass fabrication materials are as follows:

Architectural and Construction Applications

Glass is the magic material for buildings. Here is why:

- Cheaper and easier to deploy

- Aesthetic look

- Accessible

- Energy efficiency

All these crucial features of glass make it suitable for applications like:

- Windows and Curtain Walls. Tempered glass offers durability to your windows. Laminated glass creates a perfect look with a strengthened material presence.

- Skylights and Atriums. Laminated glass makes a place by allowing natural light to pass through the glass. Therefore, this glass material is famous for its skylights.

- Glass Railings and Balustrades. Glass is part of modern aesthetic views with the transparent look through the windows. It is a power-packed opportunity with both a glamorous look and strength.

Automotive Industry Applications

The automotive industry is a big fan of fabricated glass. Say thanks to the impactful appearance and strength of the glass materials.

The common parts manufactured with glass include:

- Windshields and Windows. Laminated glass is the first choice material for windshields and windows. The durability and strength of the laminated glass, along with its safety, make it the best choice for use in the windows.

- Mirrors and Rear-View Displays. The excellent finish of the glass material makes it suitable for mirrors and rear-view displays. Anti-glare features enhance the visibility of the coming vehicles or other materials. It helps in easy and speedy driving.

Electronics and Display Technologies

iPhones. Samsung phones. Many other brands are considering glass fabrication with the required strength for their display glasses. Many electronic applications use the display glass to explore better opportunities.

- Smartphone and Tablet Screens. The gorilla glass is the most famous example of the fabricated glass. The elevated strength has made it suitable for various smartphones. Tempered glass is also a favorable choice for smartphone display applications.

- Television and Monitor Screens. The recent usage of glass in TV screens has been due to fabricated features, such as Anti-glare, anti-reflective, and anti-smudge coatings. They increase the user experience and provide extensive protection from easy wear and tear.

- Touch panels. Fabricated glass is the first choice material for touchscreen phones and panels. The seamless working with transparent materials allows a good adherence to different applications.

Conclusion

Glass fabrication can get the required glass features. But the ultimate choice is to dig up the top fabrication solutions. Sometimes, finding quality suppliers who can offer CNC machines and relevant infrastructure is difficult.

But don’t worry; manufacturers like Shenxun Glass have premium quality glass fabrication. We have accurate machining tactics and elevate the precision of your glass materials. Check out the quality glass customization now!