Introduction

Are you a fan of the laminated glass? It is one of the most prominent glass materials and is a revolutionary idea in the construction industry.

The endless benefits and support make it a robust choice in all structures. Guess what? The impeccable strength has elevated the reputation of laminated glass in the industry.

Do you want to know more about laminated glass? In this article, we will discuss laminated glass and understand how it is beneficial in various applications.

What is a laminated Glass?

Laminated glass is one of the most famous materials for its extensive durability and external appeal. The premium quality look and next-gen technology make it the ultimate choice in the industry.

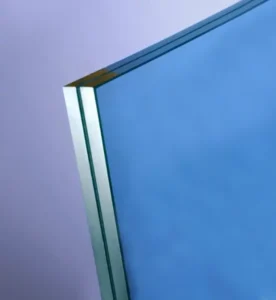

This glass material has two layers of glass with an intermediate layer of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). The interlayer holds both layers of glass and makes it difficult to break unless high stress can make it so.

Laminate glass has the following features.

- Shatter resistance. First of all, the laminated glass is tough to break. However, if it breaks, the pieces scatter instead of spreading everywhere.

- Acoustic dampening. The glass material is soundproof because the laminated layer is a game-changer.

- UV protection. The interlayer doesn’t let the UV rays pass through it. As a result, it offers protection.

How is its manufacturing process?

Laminated Glass Manufacturing involves a series of processes that ensure the proper layering and strength of the glass materials. Here are the key steps to laminate glass materials of different origins.

Preparation of Glass Sheets

What type of glass do you want to laminate? Whether it is annealed or tempered glass, preparation of the glass sheets is necessary. Cut the sheets to the desired size. Clean the glass materials thoroughly.

Adding the interlayer

The intermediate layer is the crucial tool for strength and all the features. Polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) interlayer offers the next-level durability. It can be clear, tinted, or patterned.

Bonding the layers

The bonding of the layers occurs with an intermediate layer of PVB or EVA. Rollers help remove the air pockets and prepare them for bonding. Autoclaving up to 150°C can help fuse the layers.

Quality inspections

Manufacturers further take time to monitor the quality and get the best results. The interlayer is of high quality and provides all the features.

Applications of the laminated Glass

Laminated glass is a versatile type that is useful in various modern applications. Let’s discuss how you can deploy it.

Automotive industry

Look around, and you’ll find hundreds of automotive groups offering car glass lamination. In actuality, laminated glass is famous in the automotive industry. It is because of driver safety in case of accidents. Plus, the look of the glass materials is exceptional.

Construction

You need two crucial features to deploy the glass in the construction industry. It must be resistant to damage. (Laminated Glass is already resistant.)

It should offer UV protection. ( This feature is also available.) So, a laminated glass has made its place in:

- Facades

- Skylights

- Balustrades

- Storm resistant windows

Security Glass

Have you wondered about the bulletproof security windows? You won’t believe it, but they also harness laminated glass materials because of their long-term durability and effective results. Many places, such as banks or jewelry stores, use laminated glass.

Noise Reduction

Reduce the noise or shake hands with the soundproof solutions in your rooms. The laminated glass is a good insulator for the sounds. Therefore, it is used in places such as:

- Airports

- Recording studios

- Urban offices.

Interior Design

Laminated glass has also been found to have applications in the interior design industry. You can try this material in the following ways:

- Decorative partitions

- Flooring

- Furniture

Benefits of Laminated Glass

Laminated glass plays a significant role in various applications because of various fruit-bearing features. We have sorted out the premium features that compel you to deploy this material in your applications.

Elevated safety

Laminated glass is less likely to face damage. However, under extreme temperature conditions, it can break into scattered pieces. All such pieces are harmless and avoid injury to the users. Therefore, laminated glass is a safe material.

Impact resistance

Laminated glass doesn’t break easily. The lifespan is extended. Plus, it offers unbreakable strength. A slight force can’t break it effortlessly. However, a significant force can break it into scattered pieces.

Noise insulation

Do you own a recording studio? The amplified sounds can disturb you even if you are a peace lover. In the case of laminated glass, you are more than protected. The laminated layer can absorb all the sounds and avoid damage.

UV protection

UV light can kill you. It causes skin cancers and is toxic to various other objects. However, laminated glass is also a shield against UV light. You can 99% block the UV light and save your furniture and other objects from sunlight damage.

Reduced Laminated Glass cost

The laminated glass appears to be expensive. However, it depends on the high-end glass lamination. You can go at an affordable price with a decent glass range. Moreover, the longevity of glass materials can make them more beneficial in the long term.

Versatility in color and design

Do you want the specific designs of the laminated glass? Relax! You can find it in all types of laminated glass. The full-fledged customization offers more features to users. Therefore, consumers buy laminated glass more than any other product.

Conclusion

Laminated Glass materials are aesthetically appealing and qualitative. All you have to do is dig out the laminated Glass suppliers.

Are you looking for premium-quality laminated safety glass manufacturers? Your quest ends here at the best team. Wondering who is there?

Shenxun Glass Manufacturers are premium quality laminated safety glass suppliers. You grab the next-level quality and unending performance. Plus, the customization features can help you with:

- Glass CNC processing

- Glass laser cutting

- Water jet cutting

- Color silk-screen printing

Enjoy the durability of the materials right away!