Glass is one of the excellent materials being used in every industry. From simple to extensive applications, you can explore the use of glass materials. Smartwatches, stylish art pieces, and protection materials of smartphones all comprise glass materials and show off the glamor.

Have you ever wondered what properties of glass materials make it suitable? Today, we will dive deep into all features that distinguish glass materials from others and make them appropriate.

Let’s discuss them!

What is Glass?

Glass is one of the commonly used inorganic materials that are brittle and non-crystalline. The excellent properties of glass materials make it suitable for hundreds of daily applications.

Moreover, its classy appearance has elevated its deployment over the years.

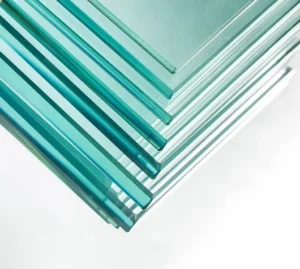

Types of Glass

Glass has to go through multiple heating and melting processes before it delivers the required features and thermal properties.

Based on various processes, we have divided glass into four key types.

-

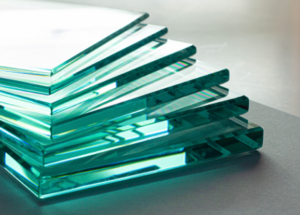

Annealed Glass

Annealing is one of the known processes in the glass manufacturing industry. First, the glass is heated to the annealing temperature and then cooled slowly to remove the internal stress factors.

Such a process gives the glass a good strength and enhances its machinability. Moreover, such glass articles are cheaper compared to other types.

-

Heat Strengthened Glass

The high heat application up to 650°C is quite impactful to create the heat strengthened glass. In this glass type, the cooling process is slow but not slower than the annealed glass.

It bestows a high strength on the heat-strengthened glass materials and makes them less likely to break. Moreover, heat-strengthened glass has a double strength compared to annealed glass but produces blunt particles like annealed glass on breakage.

-

Tempered Glass

Tempered glass is a typical material for smartphones and other glass options. Its high strength owes to the high temperature melting and then cooling rapidly with the air blasts.

The speedy cooling process strengthens it four to fivefold compared to the annealed glass. The good news is the breakage particles that are small and less likely to cause harm.

-

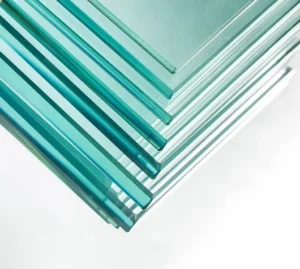

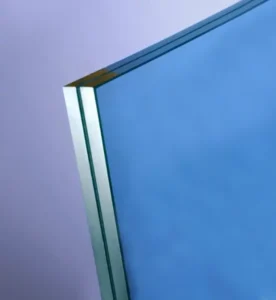

Laminated Glass

Laminated glass contains layers of glass materials with an interlayer of another material. The common materials are polyvinyl butyral or ethylene-vinyl acetate.

The goal of the laminated layer is to elevate the strength of the glass and make it more resistant to UV light. Sometimes, you can observe the elevated soundproofing features from laminated glass materials.

Composition of Glass Materials

Glass does contain a single element. Instead, it comprises various materials which deliver the expected results.

Here are a few ways to explore the composition of different glass materials.

| Glass Type | Composition Materials |

| Soda Glass | Silica (SiO₂), Sodium carbonate (Na₂CO₃), Calcium carbonate (CaCO₃) |

| Flint Glass | Silica (SiO₂), Lead oxide (PbO), Potassium oxide (K₂O) |

| Lead Crystal Glass | Silica (SiO₂), Cerium oxide (CeO₂) |

| Xena Glass | Zinc oxide (ZnO), Barium borosilicate (BaO·B₂O₃·SiO₂) |

| Crooks Glass | Silica (SiO₂), Cerium oxide (CeO₂) |

| Crown Glass | Silica (SiO₂), Potassium oxide (K₂O), Barium oxide (BaO) |

| Potash Glass | Silica (SiO₂), Potassium carbonate (K₂CO₃), Calcium carbonate (CaCO₃) |

| Pyrex Glass | Boron oxide (B₂O₃), Silica (SiO₂) |

You can notice one thing— sand or silica is a crucial component of all glass materials. It makes a significant portion of each glass type and helps in various features.

Properties of Glass Materials

Now is the time to do our work— check and compare the properties!!

Let’s talk in detail!

-

Viscosity

Viscosity is the flow of the liquid through the medium or surface. It is often a measure of internal friction. A high viscosity means the fluid is thick and less likely to flow.

The viscosity of glass helps in understanding the temperature at which customization is possible. Manufacturers take it as a working threshold and elevate the temperature to levels where viscosity is optimal for machinability.

-

Strength

Glass is brittle and solid unless you use some force. Besides, various glasses possess different degrees of strength.

What makes glass weaker!! Check out the following factors:

- Scratches or imperfections on the glass surface

- Thermal stresses

- Tiny crystals are added to it.

The strength of glass decreases dramatically upon increasing temperature.

Guess the most robust glass type. It is none other than the tempered glass. It can be 4-5 times stronger than annealed glass and withstand large breakage forces. Heat-strengthened glass is twice as strong as annealed glass.

Consider your requirements when choosing the kind of glass you need.

-

Thermal Expansion

In temperature applications, glass expands rapidly. It has led to usage in various molding applications which require the conversion to a specific shape.

The engineers have noticed the two parameters:

- Thermal Expansion Coefficient. It shows the rate of expansion of glass with the temperature increase.

- Transition Temperature. You see the onset of expansion when the temperature reaches a specific point.

Remember, thermal expansion is not the same for each glass type. Instead, silica glass has a low thermal coefficient and is less likely to expand. It leads to the complex transformation of the shapes.

-

Transparency

Who doesn’t know the transparency of the glass? A refined and classic glass material offers a see-through surface. All the coming products are visible.

You might wonder why the transparency of glass matters that much.

It is because of optical applications. Manufacturers can alter the glass transparency and manufacture optical glasses, lenses, or window materials.

-

Chemical Resistance

The glass appears inert and offers a flawless interaction with the other materials. It doesn’t react with acids or bases and provides a safer handling experience. You can store glass materials effectively in different garage stores or manufacture necessary components without the risks of damage.

-

Electrical Insulation

Glass is electrically insulated. It blocks the flow of electrons and protons and interrupts current passage from one surface to another. Therefore, you can observe the applications of glass materials in electronic devices, which not only elevate the beauty of the material but also feature the electrical insulation in the internal system.

-

Density and Weight

Technically, glass is a highly dense material with a typical density of 2.4 to 2.8 g/cm³. Such a high density makes it suitable for applications requiring dense and complex materials for extended durability.

-

Refractive Index

The Refractive Index is a measure of the light refraction and slowed speed. Typically, the refractive index of glass is 1.52, but you can alter it as needed.

Such a customization opportunity has made a place in optical instruments that require a different refractive index. Lenses of various materials harness the refractive index to accommodate the varying degrees of refraction.

-

Durability

The glass has built-in features, such as UV resistance or temperature fluctuations. With protected features, glass survives for many years without diminishing the quality. Moreover, you’ll save more money in the long run with the valuable effects.

-

Recyclability

Glass has a peerless feature for recycling. Guess what? You don’t have to worry about the quality. Even after recycling, it remains the same as it was earlier. Matchless recyclability not only reduces the burden on the environment but also nurtures a good day for the users by saving their money. You can use the same raw materials and recycle them as per needs.

-

Acoustic Features

Have you ever spoken to another person with a glass barrier in between? Well, the noise insulation is due to the glass thickness and insulation features. Users can elevate or decrease the soundproofing in their buildings and reduce the noise transmission.

Applications of Glass Materials

A humongous bunch of properties of glass materials has boosted its utilization in various applications. Let’s take a look!!

-

Electronics

Glass has dominated the electronic industry since its inception. The smartphone glass protectors come from tempered glasses. Particular glass type helps touch the screen of laptops, phones, and many technological equipment. Even more, the semiconductor wafers comprise the glass materials.

-

Automotive and Transportation

The automotive industry has many implications. From designing a windshield to the headlights, all components contain the glass to some extent. You can dig out the boats, airplanes, and helicopters using glass for various purposes.

-

Medical Industry

Many medical tools use transparent glass lenses. Optical lenses are the most common examples being used in the medical field. Moreover, X-ray machines comprise the glass and help in different tests.

-

Solar Energy

Have you seen the solar panels contain a layer of glass? Well, that is a fact now. It helps in light refraction and better entrapment of the sunlight. Therefore, energy production is optimal with the glass.

-

Decorative Industry

Many decorative pieces often come in glass packaging, elevating their beauty. Home glass windows enhance the overall glamor of the home. Many glass materials make a decent entry into the packaging centers.

Conclusion

Glass is one of the crucial components of our daily applications. Before making your first purchase, consider the premium thermal and optical features. Moreover, check the quality of the glass materials with its composition.

Do you want the best supplier for your glass materials? Shenxun glass manufacturers are the ultimate choice for glass materials. You’ll explore the premium quality glass with customized features. Check out the affordable glass materials now!