Introduction

Glass is one of the most brittle materials. Do you agree with this information? You can even listen to more interesting facts—it becomes more brittle if you don’t let it undergo the annealing process.

You might be curious about annealing glass, how it is exceptional, and how we can go through this process. If such questions irritate your nerves, this discussion is for you. We have evaluated the annealed glass process and its various aspects.

Let’s know!

What is annealed glass?

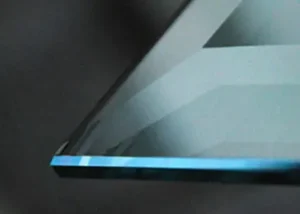

Annealed glass is a less brittle glass type with less internal stress and better particle adhesion. Compared to pure glass, it sustains external force and retains its original shape.

Mystery Unresolved: Why is glass so unbreakable?

Once, you might have asked yourself: why is glass so brittle compared to other materials?

The straightened answer is disordered arrangements of the molecules. Whenever you apply force to the glass, molecules get separated, and the glass shatters quickly.

Steps to achieve the annealed glass

The Annealing process can be very cool for glass manufacturers. It involves a cooling process and multiple steps that relieve the internal stress of the material.

Four primary steps are required to achieve annealed glass. But before that, the thickness, composition, and shape of the material must be determined.

Step 1: Achieve the Annealing Temperature

Melt the glass at a higher temperature. Check for the manufacturer’s instructions for each glass type and melting temperature.

Now, slowly cool until the annealing temperature gets under the knock. How much is the annealing temperature? Typically, it is 950°F.

Get the annealing temperature based on your glass type.

Step 2: Holding period

Once you have achieved the annealing temperature, be patient. There are some guidelines for the wait.

One hour of holding at an annealing temperature is sufficient if you have a flat glass with a quarter-inch thickness. For a glass with half an inch of thickness, you can consider two hours of holding at that temperature.

Check the glass thickness and type. Complex glass structures don’t anneal quickly, so get a longer annealing temperature wait. However, follow the instructions for a one-hour wait for a quarter-inch thickness.

Step 3: Slow Cooling

Don’t go for rapid cooling. It can cause the disordered alignment of the water molecules. So, what should you do?

Bring in a uniform cooling for the definite. Remember, thicker glass requires more time and better cooling than thinner glass.

Reduce the temperature to 5°F per minute and roughly 300°F per hour for a glass ⅛ inches in thickness. If the glass has more inches of thickness, wait longer and take it below the strain temperature thoroughly.

Step 4: Complete Cool Down Period

Have you reached below-strain temperature? Great. Now is the time to show off a rapid cooling period. Bring the temperature to the room level and check the brittle features. Indeed, the glass would be more strengthened and less likely to be brittle.

Tips to get the best out of your annealing process

Annealing is a method that is more than a no-brainer. You must know the annealing temperature for different materials and consider various parameters, such as glass complexity and types.

So, achieve the best annealing process with the correct tips:

Get the precise temperature and kiln.

For most glass types, the annealing temperature is around 950°F. Still, the material can experience ups and downs. When cooling the glass, make sure the uniform temperature decreases.

Adjustable temperature kilns are the premium options in this case.

Wait for sufficient time.

Set a standard waiting time of one hour for ¼ inch glass thickness. Please don’t wait for less or a higher temperature than the required one, as it can affect the glass annealing process.

Handle glass when cooled effectively.

Abrupt touching or handling of the glass is risky. So, take control when the glass has cooled enough.

Key benefits of annealed glass

Annealed glass is a blessing in disguise. It keeps the brittle features miles away. Here are a few benefits to know.

- Safety. Glass dropped on the floor doesn’t break easily, which is relatively safe and keeps users from risking their lives. Decreased brittleness keeps you on the better end.

- Cost-effectiveness. No expensive method is used in annealing glass. With the practical usage of the different applications, you’ll save costs and generate more.

- Workability. Cutting and drilling pure glass is difficult compared to annealed glass. So, enhance the practical implementations of your annealed glass.

- Versatility. Annealed Glass is a game-changer with next-level optimal clarity, which is why it is used in windows and display cases.

What is the difference between annealed glass and tempered glass?

Apart from annealed glass, you indeed have encountered tempered glass.

Here is how both are different from each other.

Strength

Standard annealed glass could be more robust compared to tempered glass. The powerful tempering process bestows the glass molecules with top-class strength and prevents them from breaking sooner.

Breakage Pattern

Though Annealed glass relieves stress, it produces large pieces upon breakage. When they suddenly break after a fall on the ground, they can risk users’ lives. On the other hand, tempered glass is relatively safe. It breaks into small pieces and keeps you away from the risks.

Thermal Resistance

Who do you think is more durable in front of high temperatures?

Let’s check.

Annealed glass is prone to heat. If you elevate the temperature, it can’t sustain higher temperatures and breaks easily. Tempered glass has advanced strength, making the breakage difficult. It can withstand high-temperature conditions comfortably.

Processing

Modifications are sometimes necessary in the factories. Annealed glass is the kingmaker in workability. You can mold and transform it into the desired shape without a second thought.

Forget such a facility with tempered glass. It doesn’t convert into different shapes but breaks if you take the temperature or force above the required levels.

Conclusion

It would help if you had the facilities for glass annealing. Is it expensive for you? Well, there is an option. Find custom glass manufacturers who nurture the full-fledged customization opportunity.

Shenxun Glass is one of the top custom glass manufacturers which deploys cutting-edge technology. Reinvent your glass processes and elevate its strength. Check out the variety of glass options on their site.